Kverneland 7730

Selvlæssende, bugseret drejeskiveindpakker til nem betjening

Bugseret drejebords indpakker, der håndterer rundballer op til 1000 kg

Højdepunkter

Trækkende drejepladeindpakker Skånsom læsning og aflæsning af ballen Kan håndtere rundballer op til 1000 kg DuoWrap-funktion (ekstraudstyr) for hurtigere indpakning Computerstyring giver fuldautomatisk driftBeskrivelse

Kverneland 7730 er en bugseret indpakker designet til mindre traktorer. Med et lavprofilbord til stabil indpakning og skånsom aflæsning af den indpakkede balle er den nem at bruge, og selv versionen med kabelstyring har automatisk tælling af bordrotationer og automatisk bordstop, når et korrekt antal indpakninger er afsluttet. Kverneland 7730-modellerne har mulighed for DuoWrap/HSP forstrækningsanlæg til dobbeltfilm for hurtigere indpakning. Den hydraulisk betjente læssearm er placeret i højre side og kan håndtere baller fra 1,20 m op til 1,50 m i diameter.

Højdepunkter

- Bugseret indpakker

- Bugseret indpakker med drejebord

- Designet med lav profil sikrer skånsom på- og aflæsning af ballen.

- Kan håndtere rundballer på op til 1000 kg.

- DuoWrap/HSP-funktion som ekstraudstyr til hurtigere indpakning.

- Computerversion giver fuldautomatisk drift af indpakningscyklus

Funktioner

- On the Kverneland 7710, 7730 and 7740 a hydraulically operated film cutter cuts and holds the film in position ready to wrap the next bale.

- An easy to use solution without the need to manually control the operation.

The DuoWrap sees twin film dispensers integrated into the Kverneland 7710, 7730 and 7740 mounted and trailed turntable wrappers. DuoWrap gives up to 50% faster wrapping compared to single film models, whilst also reducing the risk of film breaking during wrapping. Utilising a 66% overlap of the two films as they are applied to the bale, DuoWrap ensures even coverage without excessive wrinkling of the film.

- Two large diameter rollers, both of which are driven, ensure bale rotation even in the most difficult conditions.

- Four endless belts carry and rotate the bale evenly during wrapping with no risk of film damage.

- The two large diameter conical side support rollers ensure that the bale is kept in a central position on the rotating table during wrapping operation.

- The Kverneland 7730 and7740 are designed with a low table height and wheels located at the very rear of the machine.

- The position of rear wheels ensures a low table height provide low loading and unloading height.

- The low slung chassis combined with a short lifting height, provides fast transfer of the bale from arm to turntable.

- 1) The low mounted table design allows higher rotation speed an.

- 2) The short lifting height provides fast transfer of bale from arm to turntable.

- 3) It ensures vast and gentle on-the-move unloading with no need for a fall damper.

- The clever design of the frame with its extendable wheel arm on the right hand side allows an increase in track width on the field for maximum stability during loading of bales.

- This allows bales up to 1 ton to be loaded without any counter weights on the machine.

- For narrow transport width, the right hand wheel is turned to the inside of the support arm.

Computer Control (C)

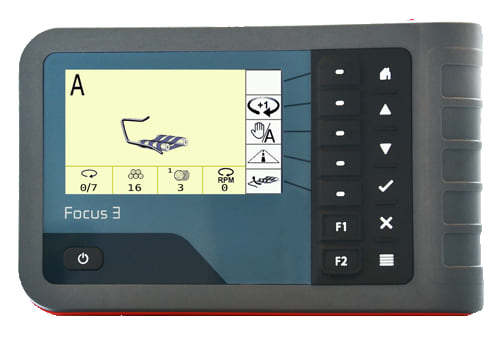

- The computer (Focus 3) controlled C models turn the wrapper into a fully automatic machine offering either a fully automatic operation or a choice of manual override or function by function operation.

- Choose for example that you want the bale to wrap automatically off. One operator does the entire process of loading, wrapping and stacking when loaded, but remain on the wrapping table until you confirm that you want to offload.

- Compact joystick allows temporary manual control of the bale loading and turntable rotation/tip.

Remote Control (R)

- An advanced remote controlled version is available as an option on C versions of turntable wrappers. Place the bale on the wrapper, press one key on the remote control, and the wrapping process starts.

- The previously wrapped bale is stacked and the next one picked up while the machine continues wrapping.

- Press another key when wrapping is completed and the bale is tipped off. One operator does the entire process of loading, wrapping and stacking.

Mechanical Cable Control (M)

- The manual versions (M) are controlled with manual cable control with levers.

- A wrap and bale counter is fitted for easier control of film layers, as well as number of bales wrapped.

- An automatic table stop that is controlled by the wrap-and-bale counter is fitted as standard.

- This converts the wrapper from manual to semi-automatic, as it allows the wrapping function to stop automatically at the set number of table revolutions.

Teknisk specifikation

Teknisk specifikation

Download brochure| 7730 M | 7730 C | ||

|---|---|---|---|

| Max bale size (m): | 1.20 x 1.50 | 1.20 x 1.50 | |

| Max bale weight (kg): | 1000 | 1000 | |

| Control function: | Cable control | Computer control |

Teknisk specifikation

Teknisk specifikation

Download brochureMax Bale Size |

Max Bale Weight |

Control System |

|

7730 M |

1.20x1.50m |

1200kg |

Manual Cable Control (M) |

7730 J |

1.20x1.50m |

1200kg |

Joystick Control (J) |