Kverneland Turbo 1100 T

Turbo T - Kultivator med høj ydeevne til alle årstider

Med Turbo T leverer Kverneland en kultivator, som er det rigtige valg til alle årstider, alle slags forhold og til et bredt anvendelsesområde fra stubbearbejdning til forberedelse af såbedet.

Beskrivelse

Kverneland Turbo er kultivatoren til alle årstider, til at udføre dyb jordløsning såvel som til såbedsforberedelse.

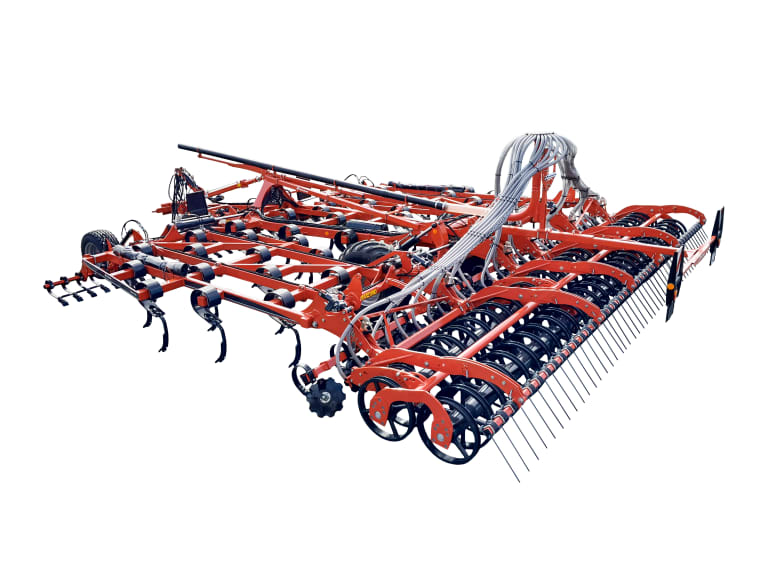

Turbo T, som bugseret model, har en veltilrettelagt tandopstilling over 5 rækker. Rækkeafstanden varierer mellem 510 mm og 900 mm; den optimerede tandposition sikrer et jævnt jordflow over hele arbejdsbredden, også omkring transporthjulene.

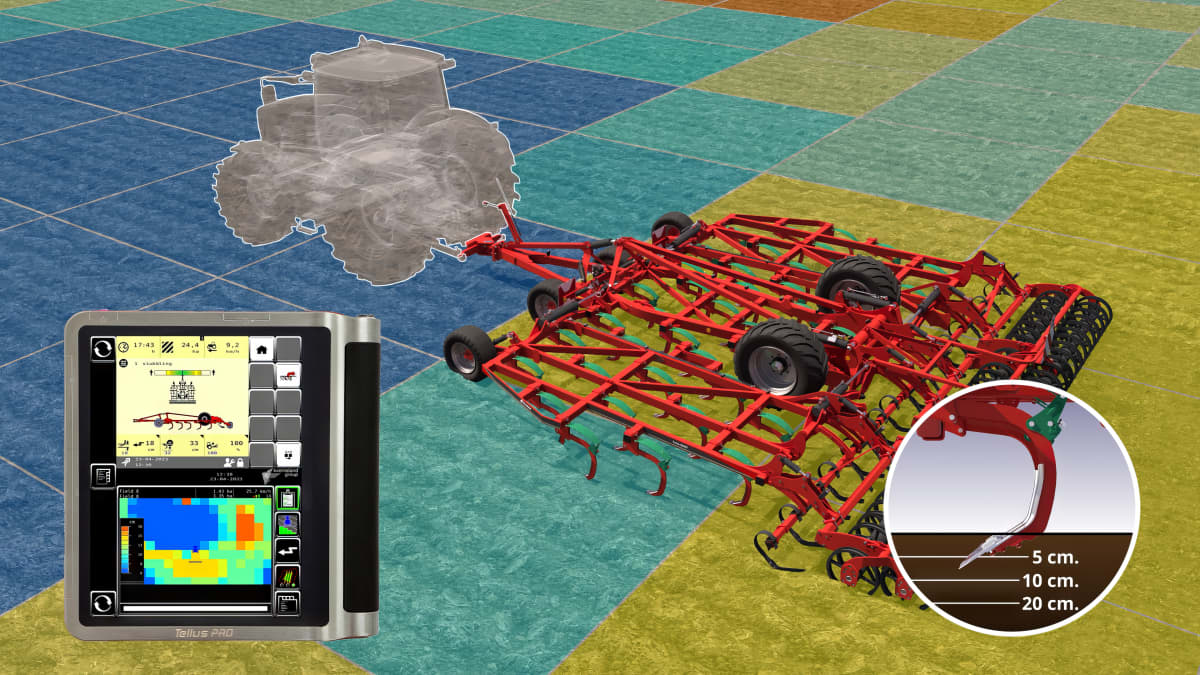

Med Turbo T, der fås i 6,50 m og 8,00 m arbejdsbredde til traktorer op til 450 hk, leverer Kverneland en kultivator, der er nem at trække til lave driftsomkostninger. En topfunktion på Turbo T er det automatiske vægtoverføringssystem (ALT). Med de forreste dybdehjul, der fungerer som detektorer, aktiverer en sensor vægtoverføringssystemet, som overfører op til 1.800 kg på trækstangen. Hjulvognen er placeret inde i redskabet for at sikre meget korte vendinger på forlandet.

Følgende dele hører til Reflex Tines:

- Vendbar spids 55 mm

- Vendbar spids 125 mm

- Gåsefod 240 mm

- Karbidspids 50 mm

- Karbidspids 160 mm

Følgende dele udstyr tilhører Triflex Tines:

- Vendbar spids 65 mm

- Knock-On spids 80 mm

- Knock-On spids 150 mm

- Knock-On spids 250 mm

- Vingeskær 240 mm

- Tiger 2 (hårdmetalspids 70)

- Karbidvingeskær 240 mm

Funktioner

Funktioner

3 steps to get a fine seedbed ready

-

Tillage the soil

The Kverneland Turbo is offering a 4 row configuration on the mounted machines and even 5 rows of tines on the trailed version. In combination with the 19cm tine distance, this leads to a nice mixing and finishing without the risk of blockages. The Turbo can be equipped with two different tines (Reflex tine or Triflex 400) and a variation of shares to adjust the machine to different conditions and tasks. -

Levelling the soil

The Kverneland Turbo is offering the choice between a levelling tine and a disc system. Both units are spring-loaded and can be adjusted in their aggressiveness. Also the angle to the ground can be adjusted. In combination with special border equipment, a perfect levelling is achieved. -

Consolidation

The third step of perfect seedbed preparation is soil consolidation. Therefore, a wide range of rollers are available to meet the various conditions and requirements.

Advanced testing program

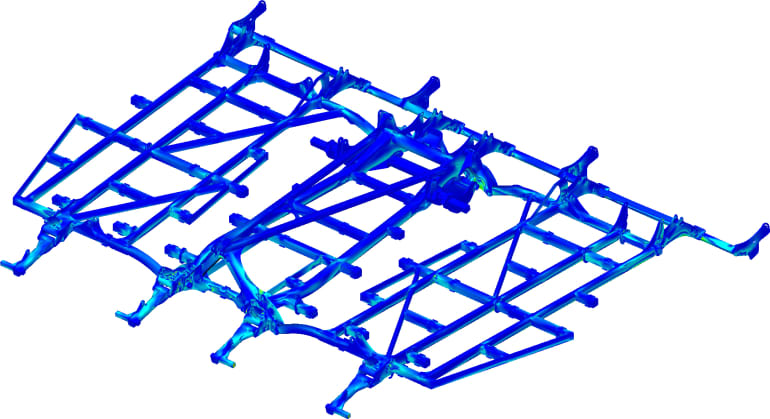

Before the Turbo was launched into the market, it had passed a whole series of tests to ensure the impeccable quality of the product.

• Sophisticated technologies are used for each development such as static load test, finite elements method (FEM) and shake-lifetime tests.

• Finally the machines are tested in the field under different conditions to reconfirm that the requirements to all functions and strength are met. A strict LOR is defined to meet all kind of soil conditions.

The frame is a result of a long study made by FEM (Finite Element Method) calculation to optimise the steel over the working width and proposing a strong structure able to resist to tractors up to 450hp for the trailed model, up to 300hp for the Turbo F and up to 175hp for the rigid frame.

The complete Turbo range has been designed to be combined with the Actipack roller, which is the heaviest roller in the range. All the most agressive scenarios (deep working when turning, headland turns, transport tests, ...) have been considered to make the different frames as strong as possible and thus guaranteeing the proven Kverneland quality.

Leaving an even surface

In order to create an even surface for a fine seedbed, Kverneland offers various options of levelling tools for the Turbo.

There are levelling tines which are a very easy and economic way of levelling and to handle normal straw conditions on light to medium soil types.

When it comes to heavy amounts of residues and also more clay or loamy soils the levelling discs are more suitable.

Both versions are overload protected by a spring to avoid damages in stony or other difficult conditions. Individual springs ensure individual release of tines or discs and keep levelling quality even in stony conditions. The pressure on this spring and also the angle of the levelling discs/tines can be adjusted for a perfect results.

To respect the transport width on the Turbo mounted versions with 3.00 and 3.50m working width the outer tines/discs can be hydraulically or mechanically folded in.

The clod board in front of the trailed models increases the crumbling effect on ploughed land and ensures active levelling due to the high vibration of the cracker tines. The aggressiveness of the clod board can be adjusted hydraulically from the cab on-the-go. In very wet conditions or if the levelling in front is not needed, the clod board bar can be easily lifted out of work.

There is a full range of levelling equipment and rear rollers available:

Actipress Twin ø 560mm - 220kg/m without soil

- U-profile for high carrying /rolling capacity in light soils

- Clod breaking also in heavy conditions

- Possibility to make different soil profiles by locking the rocking (even or corrogated)

- Self-cleaning effect thanks to the twin u-ring concept

- High stability thanks to the oscillating frame

- High and homogenous consolidation

- Can also work in stony conditions

- Weight when full of soil: 250kg/m

Actipress Single ø560mm - 150kg/m without soil

- Single rotor with U-profile for high carrying /rolling capacity on light soils

- Also for stony conditions due to wide pitch

- 3 models available for a more uniform or rough surface:

with blades/with carbide blades / without blades - More compact design and reduced weight especially suitable for three-point mounted implements.

- Clod breaking also in heavy conditions

- Weight/m when full of soil : 188 kg/m

Cage roller ø 550mm - 90kg/m

- 10 bars for a good loading capacity and operation in wet conditions

- Effective crumbling action

Double cage roller ø 400mm (tube/flat) - 160 kg/m

- Good crumbling

- Precise depth control

Actipack ø 560mm - 205kg/m

- The Kverneland Actipack roller displays its superb working qualities especially on medium to heavy soils and also in wet, stony and sticky conditions thanks to the independent skids and knives.

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation.

Actiring ø 540mm - 160kg/m

- The Actiring roller is a lighter variant of the Actipack, using the same frame structure and knife system.

- The discs have been replaced by a “V” profile ring, this is saving 60kg/m, which is of critical importance for reducing lifting requirements for mounted equipment.

- Actiring is not recommended in stony conditions.

Actiflex roller ø 580mm - 160kg/m

- The Actiflex roller has been made to create an intensive mixing with all types of conditions, even stony ones.

- The rings are made with spring steel to have a high resistance against stress at high speed.

- Actiflex rings are separated by skids to prevent any accumulation inside the roller.

- This roller is the ideal tool to create a nice seedbed and enhance the weeds regrowth after harvesting.

Easy conversion from working to transport position.

The three-part hydraulic folding gives a transport width of 3.00m and ensures smooth running and safe road transport.

The Turbo T models are EU homologated at 40km/h with pneumatic brakes. A national homologation (25km/h) with hydraulic brake is also available for specific countries.

High vibration for intensive mixing and crumbling

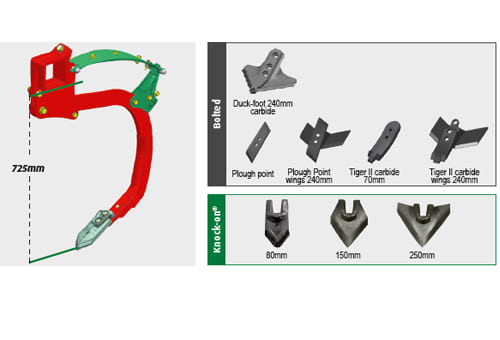

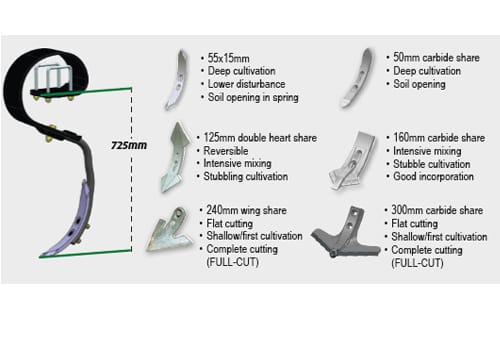

Reflex tine: versatile for all conditions

The Reflex tine benefits from high vibration effect: the large coil and the high tine clearance of 725mm gives a high flexibility whilst ensuring a high vibration effect to crack the clods and mix the soil. The working depth of the share stays even when the tine release to the back thanks to its stable design. The narrow tine spacing ensures active crumbling and perfect levelling. Thus the pressure applied on the coil is reduced to extend its life time.

The Reflex tine is the perfect solution for using the Turbo in first/second stubble pass or for seedbed preparation. Also for the incorporation of slurry or manure the Reflex tine is the best choice. To make it even more versatile three different shares are available

For stony condition and high penetration

Triflex tine 400: High stability at deep operations

The auto-reset Triflex tine 400 uses the well known Kverneland leaf spring system to ensure a high point pressure of 400kg in work and a smooth release curve when the tine hits an obstacle. The Triflex tine 400 with narrow design and special shape reduces the pulling forces while ensuring a perfect penetration in most compacted soil. It is the perfect choice for deep loosening and working on heavier soil types strewn with stones.

The Triflex tine 400 can be equipped with different shares to adapt to different working depths and tasks. 3 types of shares are available with the patented Knock-on® system. It is the easiest way of changing parts on a cultivator, either to adapt the machine to the job to be done or to change wearing parts.

3 steps to get a fine seedbed ready

-

Tillage the soil

The Kverneland Turbo is offering a 4 row configuration on the mounted machines and even 5 rows of tines on the trailed version. In combination with the 19cm tine distance, this leads to a nice mixing and finishing without the risk of blockages. The Turbo can be equipped with two different tines (Reflex tine or Triflex 400) and a variation of shares to adjust the machine to different conditions and tasks. -

Levelling the soil

The Kverneland Turbo is offering the choice between a levelling tine and a disc system. Both units are spring-loaded and can be adjusted in their aggressiveness. Also the angle to the ground can be adjusted. In combination with special border equipment, a perfect levelling is achieved. -

Consolidation

The third step of perfect seedbed preparation is soil consolidation. Therefore, a wide range of rollers are available to meet the various conditions and requirements.

There is a full range of levelling equipment and rear rollers available:

Actipress Twin ø 560mm - 220kg/m without soil

- U-profile for high carrying /rolling capacity in light soils

- Clod breaking also in heavy conditions

- Possibility to make different soil profiles by locking the rocking (even or corrogated)

- Self-cleaning effect thanks to the twin u-ring concept

- High stability thanks to the oscillating frame

- High and homogenous consolidation

- Can also work in stony conditions

- Weight when full of soil: 250kg/m

Actipress Single ø560mm - 150kg/m without soil

- Single rotor with U-profile for high carrying /rolling capacity on light soils

- Also for stony conditions due to wide pitch

- 3 models available for a more uniform or rough surface:

with blades/with carbide blades / without blades - More compact design and reduced weight especially suitable for three-point mounted implements.

- Clod breaking also in heavy conditions

- Weight/m when full of soil : 188 kg/m

Cage roller ø 550mm - 90kg/m

- 10 bars for a good loading capacity and operation in wet conditions

- Effective crumbling action

Double cage roller ø 400mm (tube/flat) - 160 kg/m

- Good crumbling

- Precise depth control

Actipack ø 560mm - 205kg/m

- The Kverneland Actipack roller displays its superb working qualities especially on medium to heavy soils and also in wet, stony and sticky conditions thanks to the independent skids and knives.

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation.

Actiring ø 540mm - 160kg/m

- The Actiring roller is a lighter variant of the Actipack, using the same frame structure and knife system.

- The discs have been replaced by a “V” profile ring, this is saving 60kg/m, which is of critical importance for reducing lifting requirements for mounted equipment.

- Actiring is not recommended in stony conditions.

Actiflex roller ø 580mm - 160kg/m

- The Actiflex roller has been made to create an intensive mixing with all types of conditions, even stony ones.

- The rings are made with spring steel to have a high resistance against stress at high speed.

- Actiflex rings are separated by skids to prevent any accumulation inside the roller.

- This roller is the ideal tool to create a nice seedbed and enhance the weeds regrowth after harvesting.

3 steps to get a fine seedbed ready

-

Tillage the soil

The Kverneland Turbo is offering a 4 row configuration on the mounted machines and even 5 rows of tines on the trailed version. In combination with the 19cm tine distance, this leads to a nice mixing and finishing without the risk of blockages. The Turbo can be equipped with two different tines (Reflex tine or Triflex 400) and a variation of shares to adjust the machine to different conditions and tasks. -

Levelling the soil

The Kverneland Turbo is offering the choice between a levelling tine and a disc system. Both units are spring-loaded and can be adjusted in their aggressiveness. Also the angle to the ground can be adjusted. In combination with special border equipment, a perfect levelling is achieved. -

Consolidation

The third step of perfect seedbed preparation is soil consolidation. Therefore, a wide range of rollers are available to meet the various conditions and requirements.

Advanced testing program

Before the Turbo was launched into the market, it had passed a whole series of tests to ensure the impeccable quality of the product.

• Sophisticated technologies are used for each development such as static load test, finite elements method (FEM) and shake-lifetime tests.

• Finally the machines are tested in the field under different conditions to reconfirm that the requirements to all functions and strength are met. A strict LOR is defined to meet all kind of soil conditions.

The frame is a result of a long study made by FEM (Finite Element Method) calculation to optimise the steel over the working width and proposing a strong structure able to resist to tractors up to 450hp for the trailed model, up to 300hp for the Turbo F and up to 175hp for the rigid frame.

The complete Turbo range has been designed to be combined with the Actipack roller, which is the heaviest roller in the range. All the most agressive scenarios (deep working when turning, headland turns, transport tests, ...) have been considered to make the different frames as strong as possible and thus guaranteeing the proven Kverneland quality.

3 steps to get a fine seedbed ready

-

Tillage the soil

The Kverneland Turbo is offering a 4 row configuration on the mounted machines and even 5 rows of tines on the trailed version. In combination with the 19cm tine distance, this leads to a nice mixing and finishing without the risk of blockages. The Turbo can be equipped with two different tines (Reflex tine or Triflex 400) and a variation of shares to adjust the machine to different conditions and tasks. -

Levelling the soil

The Kverneland Turbo is offering the choice between a levelling tine and a disc system. Both units are spring-loaded and can be adjusted in their aggressiveness. Also the angle to the ground can be adjusted. In combination with special border equipment, a perfect levelling is achieved. -

Consolidation

The third step of perfect seedbed preparation is soil consolidation. Therefore, a wide range of rollers are available to meet the various conditions and requirements.

Advanced testing program

Before the Turbo was launched into the market, it had passed a whole series of tests to ensure the impeccable quality of the product.

• Sophisticated technologies are used for each development such as static load test, finite elements method (FEM) and shake-lifetime tests.

• Finally the machines are tested in the field under different conditions to reconfirm that the requirements to all functions and strength are met. A strict LOR is defined to meet all kind of soil conditions.

The frame is a result of a long study made by FEM (Finite Element Method) calculation to optimise the steel over the working width and proposing a strong structure able to resist to tractors up to 450hp for the trailed model, up to 300hp for the Turbo F and up to 175hp for the rigid frame.

The complete Turbo range has been designed to be combined with the Actipack roller, which is the heaviest roller in the range. All the most agressive scenarios (deep working when turning, headland turns, transport tests, ...) have been considered to make the different frames as strong as possible and thus guaranteeing the proven Kverneland quality.

3 steps to get a fine seedbed ready

-

Tillage the soil

The Kverneland Turbo is offering a 4 row configuration on the mounted machines and even 5 rows of tines on the trailed version. In combination with the 19cm tine distance, this leads to a nice mixing and finishing without the risk of blockages. The Turbo can be equipped with two different tines (Reflex tine or Triflex 400) and a variation of shares to adjust the machine to different conditions and tasks. -

Levelling the soil

The Kverneland Turbo is offering the choice between a levelling tine and a disc system. Both units are spring-loaded and can be adjusted in their aggressiveness. Also the angle to the ground can be adjusted. In combination with special border equipment, a perfect levelling is achieved. -

Consolidation

The third step of perfect seedbed preparation is soil consolidation. Therefore, a wide range of rollers are available to meet the various conditions and requirements.

Advanced testing program

Before the Turbo was launched into the market, it had passed a whole series of tests to ensure the impeccable quality of the product.

• Sophisticated technologies are used for each development such as static load test, finite elements method (FEM) and shake-lifetime tests.

• Finally the machines are tested in the field under different conditions to reconfirm that the requirements to all functions and strength are met. A strict LOR is defined to meet all kind of soil conditions.

The frame is a result of a long study made by FEM (Finite Element Method) calculation to optimise the steel over the working width and proposing a strong structure able to resist to tractors up to 450hp for the trailed model, up to 300hp for the Turbo F and up to 175hp for the rigid frame.

The complete Turbo range has been designed to be combined with the Actipack roller, which is the heaviest roller in the range. All the most agressive scenarios (deep working when turning, headland turns, transport tests, ...) have been considered to make the different frames as strong as possible and thus guaranteeing the proven Kverneland quality.

High vibration for intensive mixing and crumbling

Reflex tine: versatile for all conditions

The Reflex tine benefits from high vibration effect: the large coil and the high tine clearance of 725mm gives a high flexibility whilst ensuring a high vibration effect to crack the clods and mix the soil. The working depth of the share stays even when the tine release to the back thanks to its stable design. The narrow tine spacing ensures active crumbling and perfect levelling. Thus the pressure applied on the coil is reduced to extend its life time.

The Reflex tine is the perfect solution for using the Turbo in first/second stubble pass or for seedbed preparation. Also for the incorporation of slurry or manure the Reflex tine is the best choice. To make it even more versatile three different shares are available

For stony condition and high penetration

Triflex tine 400: High stability at deep operations

The auto-reset Triflex tine 400 uses the well known Kverneland leaf spring system to ensure a high point pressure of 400kg in work and a smooth release curve when the tine hits an obstacle. The Triflex tine 400 with narrow design and special shape reduces the pulling forces while ensuring a perfect penetration in most compacted soil. It is the perfect choice for deep loosening and working on heavier soil types strewn with stones.

The Triflex tine 400 can be equipped with different shares to adapt to different working depths and tasks. 3 types of shares are available with the patented Knock-on® system. It is the easiest way of changing parts on a cultivator, either to adapt the machine to the job to be done or to change wearing parts.

Leaving an even surface

In order to create an even surface for a fine seedbed, Kverneland offers various options of levelling tools for the Turbo.

There are levelling tines which are a very easy and economic way of levelling and to handle normal straw conditions on light to medium soil types.

When it comes to heavy amounts of residues and also more clay or loamy soils the levelling discs are more suitable.

Both versions are overload protected by a spring to avoid damages in stony or other difficult conditions. Individual springs ensure individual release of tines or discs and keep levelling quality even in stony conditions. The pressure on this spring and also the angle of the levelling discs/tines can be adjusted for a perfect results.

To respect the transport width on the Turbo mounted versions with 3.00 and 3.50m working width the outer tines/discs can be hydraulically or mechanically folded in.

The clod board in front of the trailed models increases the crumbling effect on ploughed land and ensures active levelling due to the high vibration of the cracker tines. The aggressiveness of the clod board can be adjusted hydraulically from the cab on-the-go. In very wet conditions or if the levelling in front is not needed, the clod board bar can be easily lifted out of work.

There is a full range of levelling equipment and rear rollers available:

Actipress Twin ø 560mm - 220kg/m without soil

- U-profile for high carrying /rolling capacity in light soils

- Clod breaking also in heavy conditions

- Possibility to make different soil profiles by locking the rocking (even or corrogated)

- Self-cleaning effect thanks to the twin u-ring concept

- High stability thanks to the oscillating frame

- High and homogenous consolidation

- Can also work in stony conditions

- Weight when full of soil: 250kg/m

Actipress Single ø560mm - 150kg/m without soil

- Single rotor with U-profile for high carrying /rolling capacity on light soils

- Also for stony conditions due to wide pitch

- 3 models available for a more uniform or rough surface:

with blades/with carbide blades / without blades - More compact design and reduced weight especially suitable for three-point mounted implements.

- Clod breaking also in heavy conditions

- Weight/m when full of soil : 188 kg/m

Cage roller ø 550mm - 90kg/m

- 10 bars for a good loading capacity and operation in wet conditions

- Effective crumbling action

Double cage roller ø 400mm (tube/flat) - 160 kg/m

- Good crumbling

- Precise depth control

Actipack ø 560mm - 205kg/m

- The Kverneland Actipack roller displays its superb working qualities especially on medium to heavy soils and also in wet, stony and sticky conditions thanks to the independent skids and knives.

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation.

Actiring ø 540mm - 160kg/m

- The Actiring roller is a lighter variant of the Actipack, using the same frame structure and knife system.

- The discs have been replaced by a “V” profile ring, this is saving 60kg/m, which is of critical importance for reducing lifting requirements for mounted equipment.

- Actiring is not recommended in stony conditions.

Actiflex roller ø 580mm - 160kg/m

- The Actiflex roller has been made to create an intensive mixing with all types of conditions, even stony ones.

- The rings are made with spring steel to have a high resistance against stress at high speed.

- Actiflex rings are separated by skids to prevent any accumulation inside the roller.

- This roller is the ideal tool to create a nice seedbed and enhance the weeds regrowth after harvesting.

Easy conversion from working to transport position.

The three-part hydraulic folding gives a transport width of 3.00m and ensures smooth running and safe road transport.

The Turbo T models are EU homologated at 40km/h with pneumatic brakes. A national homologation (25km/h) with hydraulic brake is also available for specific countries.

Præcisionslandbrug

Præcisionslandbrug

Lavet til smart, effektivt og nemt landbrug

IsoMatch GEOCONTROL er et avanceret software-program inden for IsoMatch Tellus og IsoMatch Tellus GO+, der hjælper dig med at styre alle ISOBUS kompatible Kverneland Group maskiner såsom sprøjter, spredere og såmaskiner! Kombineret med en GPS-modtager opfylder den fremtidens behov med hensyn til nemt, smart og effektivt landbrug!

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 2 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

Connect to a local wireless network on your IsoMatch Tellus.

IsoMatch Wireless (USB-stick) is complementary to the IsoMatch Tellus and makes it easy to connect to a local wireless network, such as your phone’s hot-spot, home network etc.

No additional costs of an internet service provider. When connected via the IsoMatch Wireless you can browse the internet, view the weather, Gmail, Google, etc.

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

Teknisk specifikation

Teknisk specifikation

Download brochure| Model | Turbo 6500T** | Turbo 8000T** | |

|---|---|---|---|

| Ramme | Bugseret | Bugseret | |

| Antal tænder | 33 | 41 | |

| Arbejdsbredde (m) | 6.18 | 7.68 | |

| Valsebredde (m) | 6.50 | 8.00 | |

| Antal rækker af tænder | 5 | 5 | |

| Transportbredde (m) | 3.00 | 3.00 | |

| Rækkeafstand (mm) | Fra 510 til 900 | Fra 510 til 900 | |

| Træk | CAT. III & IV N, fast øje, Scharmüller-kuglekobling ø80 | KAT. III & IV N, fast øje, Scharmüller-kuglekobling ø80 | |

| Frihøjde under bjælke (mm) | 725 | 725 | |

| Tandafstand (mm) | 190 | 190 | |

| Indstilling af dybde | Hydraulisk ved hjælp af afstandsstykker | Hydraulisk med afstandsstykker | |

| Voldjævnere | T- eller tallerkenvoldjævnere | T- eller tallerkenvoldjævnere | |

| Tredobbelt fingerharve*** | ø 16 mm; længde 750 mm | ø 16mm; længde 750mm | |

| Valser | Rørvalse (ø 550mm), dobbelt rørvalse (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Rørvalse (ø 550mm), dobbelt rørvalse (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | |

| Transporthjul | 500/60 × 22.5 (2x) | 500/60 × 22.5 (2x) | |

| Dybdehjul | Standard - 340/55 x 16 (4x) | Standard - 340/55 x 16 (4x) | |

| Bremser | Hydraulisk eller pneumatisk | Hydraulisk eller pneumatisk | |

| Min/Max HP | 200/350 | 240/450 | |

| Totalvægt med rørrulle (kg)* | 5,845 | 6,505 | |

| Samlet vægt med Actiflex (kg)* | 6,190 | 6,900 | |

| Samlet vægt med Actipack (kg)* | 6,600 | 7,400 |

* Vægtene er angivet som en indikation.

** Bugseret Turbo T også som ISOBUS kultivator Turbo T i-Tiller

*** Tredobbelt fingerharve med mekaniske dybdekontrolhjul - ingen valse bag mulig

Teknisk specifikation

Teknisk specifikation

Download brochureModel |

Frame |

No. of tines |

No. of tine rows |

Working width / transport width (m) |

Turbo 6500T i-Tiller |

trailed fold |

33 |

5 |

6.18 / 3.00 |

Turbo 8000T i-Tiller |

trailed fold |

41 |

5 |

7.68 / 3.00 |

Advantages:

Automatic site-specific tillage

Versatile - from shallow to medium

Complete cutting, perfect mixing & levelling

Low pulling force needed

Large performance at high speed

* Vægtene er angivet som en indikation.

** Bugseret Turbo T også som ISOBUS kultivator Turbo T i-Tiller

*** Tredobbelt fingerharve med mekaniske dybdekontrolhjul - ingen valse bag mulig

IsoMatch Tellus GO+

IsoMatch Tellus GO+

IsoMatch InLine

IsoMatch InLine

IsoMatch Global 2

IsoMatch Global 2

IsoMatch MultiEye

IsoMatch MultiEye