Kverneland Exacta CL

Mester i det mellemstore segment.

CL-sprederen er mester i det mellemste segment.

Beskrivelse

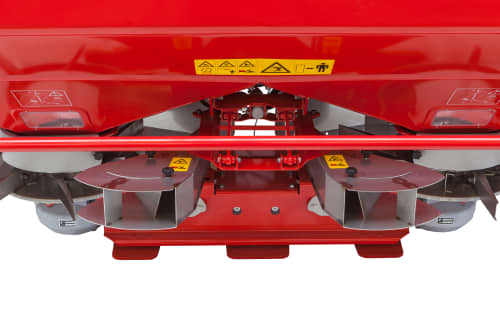

Kverneland Exacta CL er medium i størrelse og volumen, men kan sprede op til 28 m og leveres som standard med CentreFlow-systemet. Den leveres også med 8 skovle pr. skive for at opnå samme spredningskvalitet som de større spredere. CL-sprederen kan udstyres med det meste af det tilbehør, der hører til større spredere, f.eks. aluminiumsforlængelser til beholderne, ExactLine til randspredning, parkeringsramme eller LED-lys. CL-sprederen kan betjenes hydraulisk eller elektrisk. Den elektrisk styrede spreder kan betjenes fra traktoren via Remote Control II-computeren.

Funktioner

Funktioner

- With Exacta Remote II, you can operate the spreader from the closed tractor cab!

- The operating panel provides all the functions to start and stop the spreader, to set the right application rate and to increase and decrease the application rate on the move. The latest settings are retained in the memory function.

- Both discs can be shut off independently to spread half working width.

- Specially sealed actuators are used to cope with corrosive conditions.

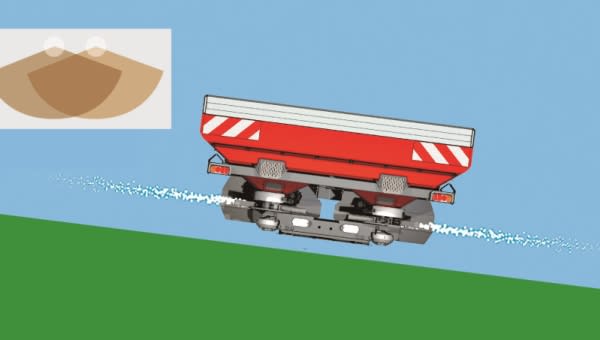

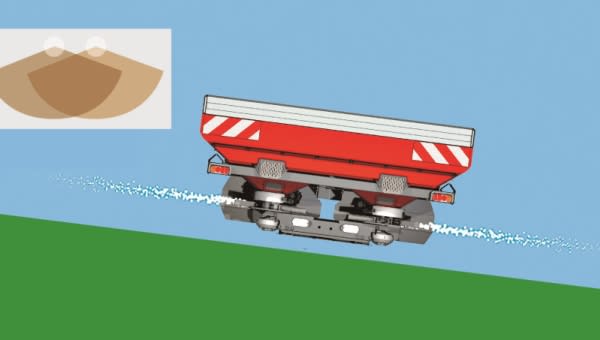

- No impact, no fragmentation, no dust: Central release point, smooth acceleration and centrifugal force accelerates fertiliser up to disc speed before it reaches the vane.

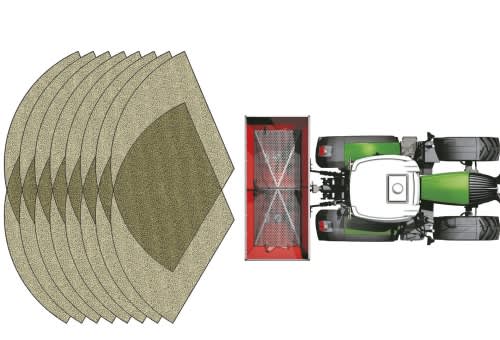

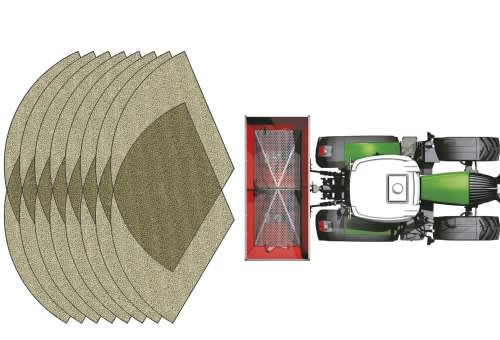

- Accurate spreading pattern: A double overlap spreading pattern gives unrivalled accuracy. The 8 vanes per discs are ensuring a continous flow of fertiliser to the field. This is important for high capacity spreading and forward speed.

- Minimal wind influence, maximum tolerance: Flat discs and a horizontal flow of fertiliser give a symmetrical spreading pattern.

- Consistent spreading pattern: Eight vanes per disc, eight sectors per revolution give an equal distribution. Double overlap spreading pattern.

- Guaranteed accuracy on slopes: guaranteed accuracy on slopes. The fertiliser always contacts the vanes at the same point, also on slopes and travels the complete length of the vane.

- Easy to assemble aluminium hopper extensions are available to increase hopper capacity.

- An easy to fold in and out hopper cover is as option availble. Simple to fit!

- Left/right shut off valve for spreading at half working widths is optional available.

- To ensure a consistent flow when spreading low quantities, the CentreFlow system is equipped with a fine application kit. Ideal for spreading low quantities, seeds and slug pellets.

- Delta shaped heavy duty grids are standard equipment of the Exacta CL spreader.

- A hopper emptying kit is available for easy emptying of the last fertiliser granules out of the hopper.

- A tramline cylinder, manual or hydraulic border spreading plate or ExactLine border spreading device can be ordered for easy border spreading.

- Long life LED lights are optional available.

- Kverneland offers the ExactLine system or manual/hydraulic border spreading plate for border spreading. The ExactLine can be accurately set for all types of fertiliser and for all working widths. Operation is easy, no need to leave the tractor seat. For the HL, TL and TLX models the ExactLine can even be fitted on the left and right hand side of the spreader.

- With one-side boundary spreading the tractor is driven approximately 2 metres from the field border.

- With boundary track spreading the tractor is driving in the first tramline and is spreading to the border. The distance to the border is the half of the working width.

- The Border Spreading Indicator (BSI), indicates which border spreading device is active.

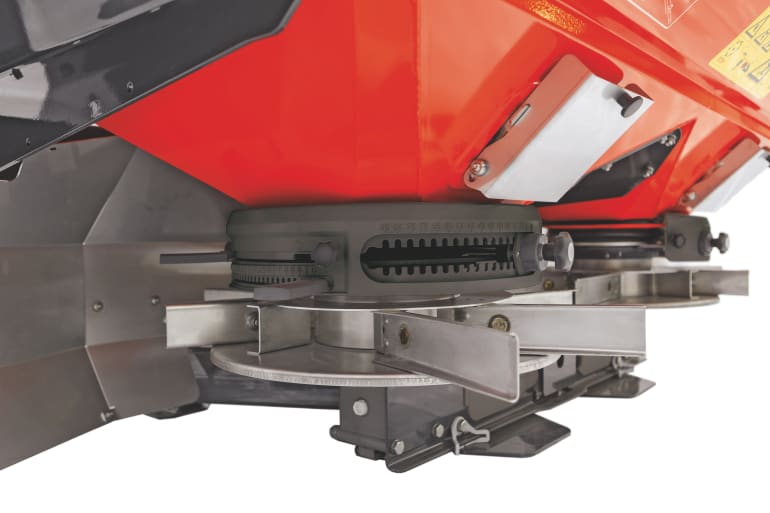

- The compact EasySet 'dashboard' gives you considerably simplified accurate setting and adjustment of application rates. Two hydraulically operated metering plates, each with three discharge openings ensure an equal fertiliser flow from the hopper to the spreading discs.

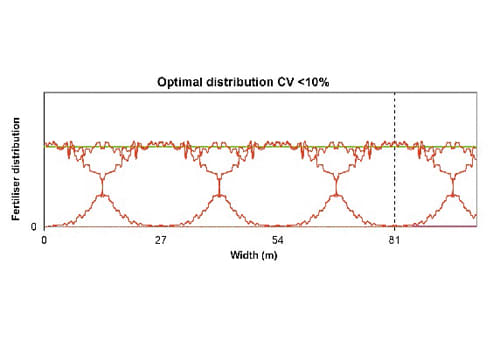

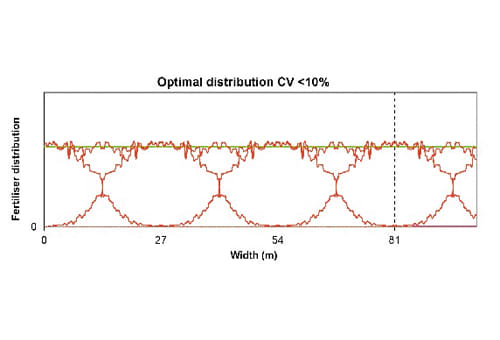

- The development department of Kvernelands spreader R&D team has its own spreader competence centre in order to allow continuous testing throughout the year. All test are carried out according to the strictest international standards and quality requirements.

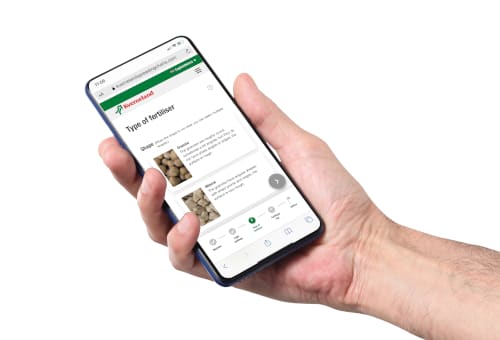

- The key to accurate spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible. The Kverneland Exacta checklist helps you to ensure consistent accuracy in all field conditions

1. Select fertiliser type

2. Determine granule size and distribution

3. Determine litre weight

- Direct access to the most recent test results at: www.kvernelandspreadingcharts.com or download the spreading charts Application via the App Store or get it on Google Play

- No impact, no fragmentation, no dust: Central release point, smooth acceleration and centrifugal force accelerates fertiliser up to disc speed before it reaches the vane.

- Accurate spreading pattern: A double overlap spreading pattern gives unrivalled accuracy. The 8 vanes per discs are ensuring a continous flow of fertiliser to the field. This is important for high capacity spreading and forward speed.

- Minimal wind influence, maximum tolerance: Flat discs and a horizontal flow of fertiliser give a symmetrical spreading pattern.

- Consistent spreading pattern: Eight vanes per disc, eight sectors per revolution give an equal distribution. Double overlap spreading pattern.

- Guaranteed accuracy on slopes: guaranteed accuracy on slopes. The fertiliser always contacts the vanes at the same point, also on slopes and travels the complete length of the vane.

- The compact EasySet 'dashboard' gives you considerably simplified accurate setting and adjustment of applicaton rates. Two hydraulically operated metering plates, each with three discharge openings ensure an equal fertiliser flow from the hopper to the spreading discs.

- The development department of Kvernelands spreader R&D team has its own spreader competence centre in order to allow continuous testing throughout the year. All test are carried out according to the strictest international standards and quality requirements.

- The key to accurate spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible. The Kverneland Exacta checklist helps you to ensure consistent accuracy in all field conditions

1. Select fertiliser type

2. Determine granule size and distribution

3. Determine litre weight

- Direct access to the most recent test results at: www.kvernelandspreadingcharts.com or download the spreading charts Application via the App Store or get it on Google Play

- Kverneland offers the ExactLine system or manual/hydraulic border spreading plate for border spreading. The ExactLine can be accurately set for all types of fertiliser and for all working widths. Operation is easy, no need to leave the tractor seat. For the HL, TL and TLX models the ExactLine can even be fitted on the left and right hand side of the spreader.

- With one-side boundary spreading the tractor is driven approximately 2 metres from the field border.

- With boundary track spreading the tractor is driving in the first tramline and is spreading to the border. The distance to the border is the half of the working width.

- The Border Spreading Indicator (BSI), indicates which border spreading device is active.

- Easy to assemble aluminium hopper extensions are available to increase hopper capacity.

- An easy to fold in and out hopper cover is as option availble. Simple to fit!

- Left/right shut off valve for spreading at half working widths is optional available.

- To ensure a consistent flow when spreading low quantities, the CentreFlow system is equipped with a fine application kit. Ideal for spreading low quantities, seeds and slug pellets.

- Delta shaped heavy duty grids are standard equipment of the Exacta CL spreader.

- A hopper emptying kit is available for easy emptying of the last fertiliser granules out of the hopper.

- A tramline cylinder, manual or hydraulic border spreading plate or ExactLine border spreading device can be ordered for easy border spreading.

- Long life LED lights are optional available.

- No impact, no fragmentation, no dust: Central release point, smooth acceleration and centrifugal force accelerates fertiliser up to disc speed before it reaches the vane.

- Accurate spreading pattern: A double overlap spreading pattern gives unrivalled accuracy. The 8 vanes per discs are ensuring a continous flow of fertiliser to the field. This is important for high capacity spreading and forward speed.

- Minimal wind influence, maximum tolerance: Flat discs and a horizontal flow of fertiliser give a symmetrical spreading pattern.

- Consistent spreading pattern: Eight vanes per disc, eight sectors per revolution give an equal distribution. Double overlap spreading pattern.

- Guaranteed accuracy on slopes: guaranteed accuracy on slopes. The fertiliser always contacts the vanes at the same point, also on slopes and travels the complete length of the vane.

- The compact EasySet 'dashboard' gives you considerably simplified accurate setting and adjustment of applicaton rates. Two hydraulically operated metering plates, each with three discharge openings ensure an equal fertiliser flow from the hopper to the spreading discs.

- The development department of Kvernelands spreader R&D team has its own spreader competence centre in order to allow continuous testing throughout the year. All test are carried out according to the strictest international standards and quality requirements.

- The key to accurate spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible. The Kverneland Exacta checklist helps you to ensure consistent accuracy in all field conditions

1. Select fertiliser type

2. Determine granule size and distribution

3. Determine litre weight

- Direct access to the most recent test results at: www.kvernelandspreadingcharts.com or download the spreading charts Application via the App Store or get it on Google Play

- Kverneland offers the ExactLine system or manual/hydraulic border spreading plate for border spreading. The ExactLine can be accurately set for all types of fertiliser and for all working widths. Operation is easy, no need to leave the tractor seat. For the HL, TL and TLX models the ExactLine can even be fitted on the left and right hand side of the spreader.

- With one-side boundary spreading the tractor is driven approximately 2 metres from the field border.

- With boundary track spreading the tractor is driving in the first tramline and is spreading to the border. The distance to the border is the half of the working width.

- The Border Spreading Indicator (BSI), indicates which border spreading device is active.

- Easy to assemble aluminium hopper extensions are available to increase hopper capacity.

- An easy to fold in and out hopper cover is as option availble. Simple to fit!

- Left/right shut off valve for spreading at half working widths is optional available.

- To ensure a consistent flow when spreading low quantities, the CentreFlow system is equipped with a fine application kit. Ideal for spreading low quantities, seeds and slug pellets.

- Delta shaped heavy duty grids are standard equipment of the Exacta CL spreader.

- A hopper emptying kit is available for easy emptying of the last fertiliser granules out of the hopper.

- A tramline cylinder, manual or hydraulic border spreading plate or ExactLine border spreading device can be ordered for easy border spreading.

- Long life LED lights are optional available.

- With Exacta Remote II, you can operate the spreader from the closed tractor cab!

- The operating panel provides all the functions to start and stop the spreader, to set the right application rate and to increase and decrease the application rate on the move. The latest settings are retained in the memory function.

- Both discs can be shut off independently to spread half working width.

- Specially sealed actuators are used to cope with corrosive conditions.

Teknisk specifikation

Teknisk specifikation

Download brochure| Exacta CL | ||||

|---|---|---|---|---|

| Kapacitet af beholder (l) | 1100 | 1550 | 2000 | |

| Påfyldningshøjde (cm) | 100 | 119 | 138 | |

| Bredde (cm) | 220 | 220 | 220 | |

| Fyldbredde (cm) | 214 | 214 | 214 | |

| Tomvægt (kg) | 330 | 355 | 380 | |

| Spredningsbredde (m) | 10-24 (27-28)* | 10-24 (27-28)* | 10-24 (27-28)* | |

| Udbytte (kg/min) | 10-320 | 10-320 | 10-320 | |

| Kontrolelementer | Hydraulisk/elektrisk | Hydraulisk/elektrisk | Hydraulisk/elektrisk | |

| LED-belysningssæt | Tilvalg | Tilvalg | Valgmulighed | |

| Kantspredningsplade | Valgmulighed | Valgmulighed | Valgmulighed | |

| ExactLine-grænseudbredelsessystem | Valgmulighed | Valgmulighed | Valgmulighed |

*Afhænger af gødningstype og vaner.

Teknisk specifikation

Teknisk specifikation

Download brochureExacta CL |

CL 1100 |

CL 1550 |

CL 2000 |

Hopper capacity (l) |

1100 |

1550 |

2000 |

Filling height (cm) |

100 |

119 |

138 |

Width (cm) |

220 |

220 |

220 |

Filling width (cm) |

214 |

214 |

214 |

Empty weight (kg) |

325 |

350 |

375 |

Spread width (m) |

10 - 24 (27/28)* |

10 - 24 (27/28)* |

10 - 24 (27/28)* |

Output (kg/min) |

10 - 320 |

10 - 320 |

10 - 320 |

*Afhænger af gødningstype og vaner.