Kverneland Densus 7090

Ny generation af ballepressere med variabelt kammer

Ballepresser med variabelt kammer og ballediameter fra 0,70 m op til 1,85 m

Beskrivelse

Kverneland Densus 7090-presserne er designet til at producere velformede baller med høj densitet, som er afgørende, når man høster værdifuldt vinterfoder og strøelse.

Fantastisk formede baller ser godt ud og giver praktiske fordele som forbedret stabling, transport og opbevaringseffektivitet. Kverneland Densus 7090 tilbyder omkostningseffektiv drift på grund af hurtige cyklustider, højt output under alle afgrødeforhold og lave vedligeholdelseskrav. Kverneland Densus 7090 har forskellige funktioner, der forbedrer presseprocessen. De omfatter fire slidstærke endeløse bælter, en indløbsrotor med større diameter, en 2,30 m bred pickup med to kamme og det berømte PowerBind-system til direkte indføring af net. Disse komponenter er designet til at øge din produktivitet og forbedre kvaliteten af dine baller

Højdepunkter

2,30 m pick-up med stor arbejdsbredde

15 enkeltbeskyttede knive til snitning

Højkapacitetsrotor med en diameter på 520 mm

Effektiv og pålidelig PowerBind-binding

Nem og enkel ilægning af netruller

Unikt, let at betjene Intelligent Density 3D System

Intuitiv styring med Focus 3 og ISOBUS-terminal

Funktioner

Funktioner

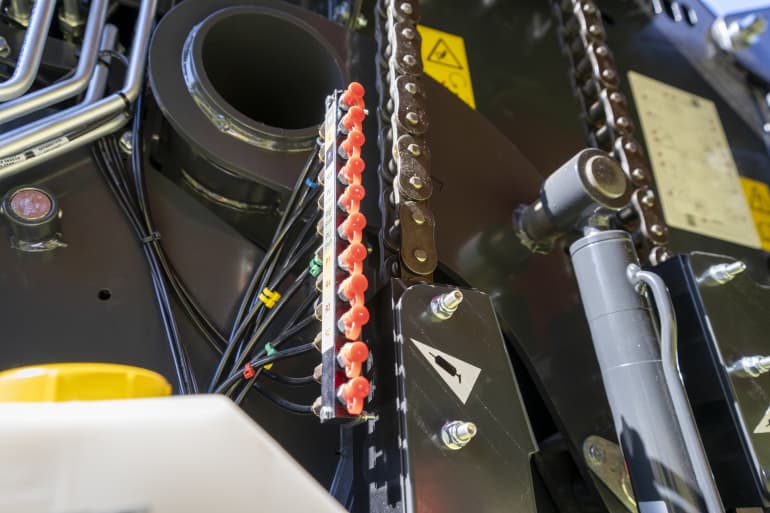

- Each bearing is clearly marked from the greasing bank making the maintenance simple.

- External bearings are reducing the service time to the minimum.

- Automatic chain lubrication with individually adjustable outlets.

ISOBUS Control

IsoMatch Tellus

The IsoMatch Tellus is the new virtual terminal, offering 2 Interface screens in 1 terminal. The large 12” easily programmable touch screen offers ergonomic use and is designed for long days of operation.

Due to the increasing number of functionalities that can be added to a machine such as cameras, the operator can use the baler interface in the top screen and a camera display in the bottom screen, to monitor finished bales.

Another possibility is to use the baler interface in the top screen and the tractor interface screen at the bottom.

IsoMatch Tellus GO+

IsoMatch Tellus Go is a full Isobus terminal able to control all Isobus machines in a very simple way.

Compact design makes it easy to integrate in the tractor cab despite the comfortable 7" touch screen allowing perfect machine set-up and control. With hard keys combined with the rotary switch on right hand side, for direct access to main functions while driving.

Focus 3 Control

Kverneland Group Mechatronics has recently launched a new operator terminal, the Focus 3. This terminal is developed for specific implement types and will only be delivered as package for those implements, together with the electronics for balers. The terminal Focus 3 is positioned in the market as an economy solution.

Focus 3 terminal is easy to learn and very intuitive, with focus on functionality and operating simplicity.

Focus 3 terminal is a universal control terminal which can also be used with other implements from Kverneland Group.

Focus 3 terminal gives you full control of all functions from the tractor cab. They are shown on a large and very clear digital display.

- Thanks to the actuator and work light kit, control the net brake directly from the binding and maintain easily the machine even during long days.

- Kverneland Densus balers feature the patented front-mounted PowerBind net system, eliminating troublesome feed rollers and boasting a market-leading cycle time.

- The PowerBind injection arm continuously retains the net. When the bale is 90% complete, the arm moves forward in preparation for net injection.

- When the bale is 100% complete, the net is fed flat and tight for accurate and reliable injection. PowerBind ensures a professional job without wind or crop interference.

- Low net loading height

- PowerBind offers a convenient and time-saving solution with its low loading height, allowing for easy replacement of rolls.

- A combination of three rollers and four endless belts provide smooth bale rotation and minimal crop losses, even when working in dry brittle straw.

- Hydraulic belt tensioner and fast tailgate operation place the variable series in the top list of most efficient round balers in the market.

- Spiral profile scrapper roller for efficient cleaning effect in all condition.

- Profiled rollers provide instant bale formation and are equipped with self cleaning scrapers designed for working in all crop conditions.

ChopFeed25

- The ChopFeed25 pre-chopping system offers the ultimate solution for short chop baling with a chop length of 40mm. The short and precise chop provides dense, airtight bales for the best possible quality of silage.

- The operator can choose to engage 25, 13, 12, 6 or 0 knives, giving maximum flexibility of operation.

- The ChopFeed25 knives are fitted with dual-action protection against foreign objects. Each knife is individually spring-protected and can move in two directions

ChopFeed14

- The ChopFeed14 knife chopping system provides a fast and efficient flow into the baler. With a chopping length of 70 mm, it is the ideal solution for producing tight bales with superb silage quality.

- Each knife is spring-protected against foreign obstacles. The knife will immediately return to its position once the obstacle has passed.

PowerFeed Rotor Intake

- Truly impressive intake capacity can be achieved with the PowerFeed rotor intake system - easily handling all crop types, whatever the conditions.

- The PowerFeed rotor with its 13 rotor fingers proactively forces the material into the bale chamber for higher intake speed and capacity proving instant bale start.

DropFloor

- The ChopFeed15 intake feature comes equipped with the highly effective Vicon Parallelogram drop floor system, which makes clearing blockages faster and easier. Unlike traditional systems that only lower the rear edge of the drop floor, this system also lowers the front section of the floor where blockages are more likely to occur.

- 2.0m Pick-up on EasyFeed version with 4 tines bar

- 2.30m Pick-up on PowerFeed and ChopFeed version

- Twin cam tracks on the 2.3m wide pick-up.

- Tine bars with two central supports on the 2.3m wide pick-up.

- Small diameter pick-up design.

- Roller crop press is standard on the 2.0m and 2.3m wide pick-up.

- Narrow transport width.

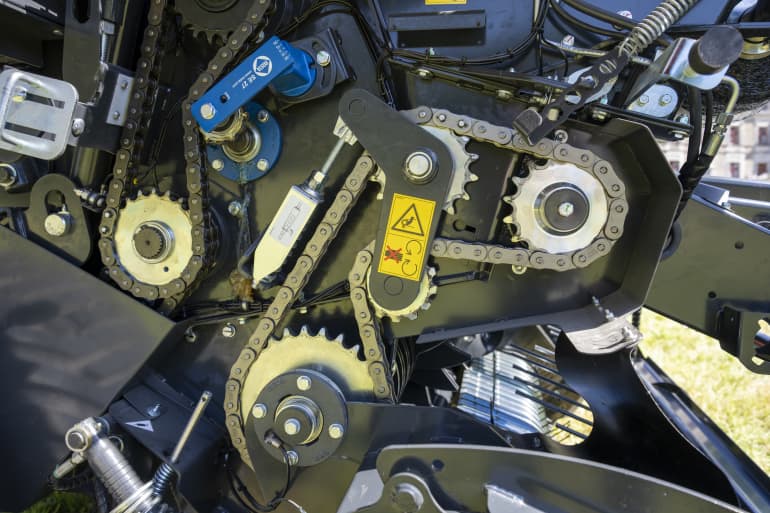

- The one piece integrated input gearbox ensures long life time and requires minimal horsepower.

- Our intake rotor and all bale chamber drives are equipped with heavy-duty 1¼” pitch chains, ensuring durability and high performance.

Kverneland Sync for Balers – Real-Time Performance, Anytime

Always Connected – Smarter Baling Made Simple

With Kverneland Sync, your baler is continuously connected to IsoMatch FarmCentre, providing real-time access to critical machine parameters and performance indicators. This seamless connectivity keeps you and your team up to date on essential baler metrics, ensuring smooth, uninterrupted operations.

Remote Service – Minimize Downtime with Kverneland ServiceCentre

Kverneland ServiceCentre integration allows technicians to remotely diagnose and address any issues with your baler, minimizing downtime and ensuring you're always ready for the next job.

Additionally, Kverneland Sync enables geofencing to help protect your baler against theft, and an accumulator lets you locate your machine even when it’s not connected to a tractor.