Optima RS

Klar til høj ydeevne og største præcision

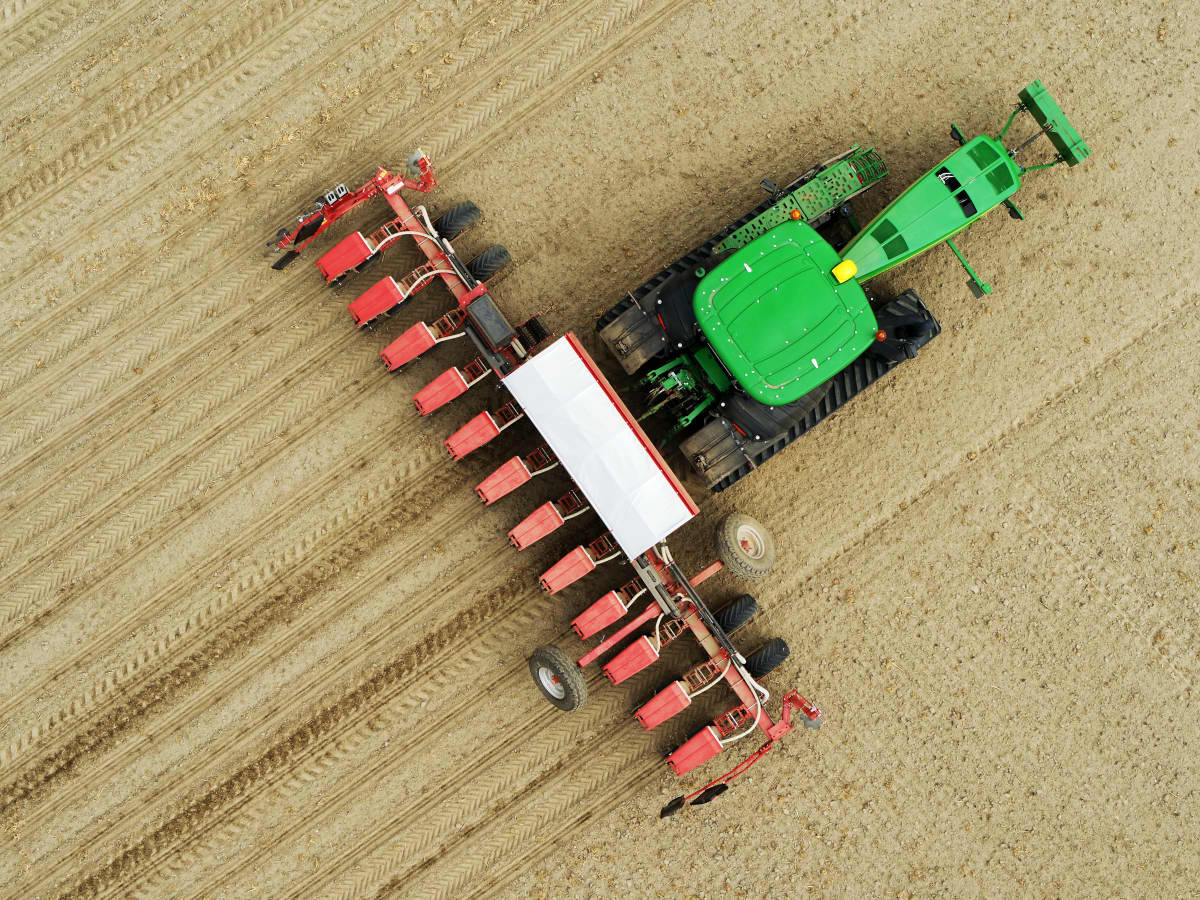

Den faste og solide Kverneland Optima RS luftpræcisionsboremaskine til høj ydeevne og output.

Højdepunkter

- Solidt og nemt rammedesign

- Fleksibel tilpasning til forskellige rækkebredder

- Komplet funktionskontrol fra førerhuset

- GEOCONTROL og GEOSEED

- ISOBUS-intelligens

Beskrivelse

Luftpræcisionssåmaskine Optima RS med fast ramme er designet til landmænd og entreprenører, der leder efter en solid og effektiv løsning. Optima RS-rammen fås i arbejdsbredde fra 6,1 m til 9,3 m

Den kan justeres til forskellige rækkebredder, fra 35 cm til 80 cm i lige og ujævne konfigurationer med op til 18 rækker. Den kan udstyres med hele udvalget af Kverneland-såmaskiner: Optima HD-II, standard- eller tandem-såmaskine i mekanisk eller e-drive II-version.

Optima RS-rammen kan udstyres med en stor 2000 l gødningstragt eller kombineres med en fronttragt. Desuden fås den elektrisk drevne mikrogranulattildeingssåmaskine.

For sikker vejtransport fås en stærk transportanordning i længderetningen

Funktioner

Funktioner

Up to 18km/h for utmost efficiency

- Optimum depth control due to the heavy basic weight of the sowing unit with the possibility to add additional pressure (up to 100kg) onto each individual sowing unit via spring-loaded system.

- Effective ground contour following due to the large depth control by open gauge wheels (⌀410mm, with 120mm)

- Precise seed placement by the small coulter which forms a clean furrow. Good placement, and seed covering is done by the smooth flexible intermediate press wheel and multi-adjustable V-press wheel.

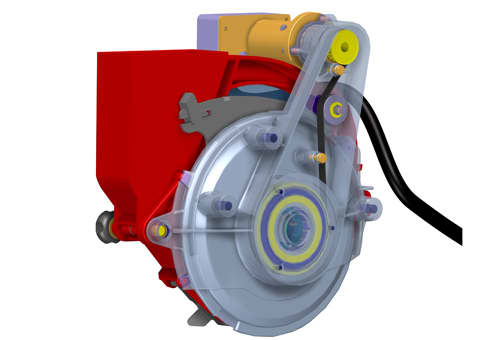

Seeding heart – Optima SX

- With the pressurized seeding heart, the seeds are “shot” by an airstream of up to 70kph into the furrow. A smooth, flexible intermediate press wheel catches and protects the delicate seeds. Any negative impact such as vibration on the way between release point and soil contact are eliminated due to the high air stream.

- The seeds reach their perfect position in the soil. Each sowing row is electrically powered by ISOBUS connection. An additional generator or other power sources are not required. The complete power supply and control is via ISOBUS.

e-drive/e-drive II – complete control and monitoring of the machine from the tractor cab in accordance with ISOBUS standard

- With e-drive/e-drive II, each sowing unit is driven individually via an electric motor.

- The low-maintenance drive is connected directly to the seeding heart via a toothed belt in an encapsulated dust proof housing.

- This enable an extremely compact design and smooth drive characteristics with low current consumption

- All the data is entered and read out via an ISOBUS terminal like IsoMatch Tellus PRO or Tellus GO.

- The sowing distances are infinitely adjustable and can be changed during sowing.

- All the sowing units can be switched off individually.

- In conjunction with “close row” sowing widths of 37.5cm a further benefit of the e-drive/e-drive II comes into play: Individual tramline switching. Tramlines can be set up for any spray width.

- The e-drive/e-drive II features complete electronic monitoring of all machine functions including seed monitoring via an opto sensor.

- Stable design, modular system, low maintenance costs, high degree of wear resistance and optimum depth placement.

- For fertiliser placement Kverneland supplies hoppers for different applications.

- The chain drive for metering can be adjusted from 106 to 390kg per hectare at a distance between rows of 75cm.

- The fertilizer applicator is driven centrally by an easily accessible side mounted gear box.

- Fertilising coulter, standard seeding with narrow coulter design and stable, reliable construction, coil spring protection from sideways forces

- Mulch seeding notched double-disc coulter for blockage-free and precise fertiliser placement by a Ø 350mm notched double-disc coulter.

- All Optima models can be equipped with micro granule applicators. The hoppers are made of special grade plastics and have a capacity of 35 litres. Depending on the working width the hoppers supply 2 to 3 seeding units.

Micro-drill for Optima HD-II and SX sowing units

The demand for microgranule applicators is increasing. Micro nutrients and also small amounts of insecticides or fungicides ensure the best start of the crop.

The electric driven micro-drills for the Optima HD-II and SX sowing units have been designed as backpack behind the sowing units and offer a hopper capacity of 17 liters.

They are electrically driven and ISOBUS controlled. The metering device consists of a wear-resistant plastic housing with exchangeable cell wheels made of stainless steel. This ensures the precise metering of the micro granules.

Operator’s safety

The engineers had focus on highest level of operator’s safety by offering easy and safe handling of the applicator. Therefore, the operator can exchange the cell wheels even when the hoppers are full of micro granule. There is no need to empty them first, reducing the operator’s risk of getting in direct contact with the granules.

A plus for the environment

The micro granules fall freely into the seed furrow without any air support, minimising the emission of dust. Therefore, the new micro-drill fully complies with the current guidelines for emission control of any granules applied.

Precision Farming

The comfortable, fully ISOBUS integrated control system allows the adaption to the stop and starting points of the seed row. This ensures precise shutting on and off at the end of the field and in tramlines (without overlaps or faults).

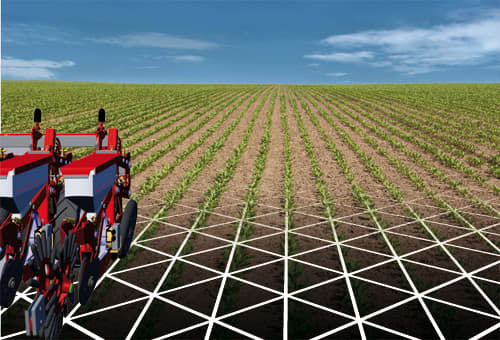

GEOSEED - Precision at high end

GEOSEED is offered in two different levels:

GEOSEED Level 1 is the synchronization in the machines working width. This improves the distribution of seeds up to perfection in parallel or diamond pattern: Positive effects are the best use of nutrients, water and sun. Also the wind and water erosion is decreased.

GEOSEED Level 2 is the synchronization in the whole field. This is the necessary requirement for interrow cultivation, also across the seeding direction. GEOSEED is the only system in the world, that makes this mechanic weeds control possible!

IsoMatch GEOCONTROL - Cost saving with immediate payback

Seeding with GPS and GEOCONTROL in combination with an electric driven precision drill is a major step towards precision and cost saving. These machines are all equipped with ISOBUS technology which with the help of the IsoMatch Tellus terminal, can be easily controlled.

Each electric driven seeding element, in combination with GPS and GEOCONTROL, is automatically switched on or off in exactly the right place, ensuring there is no overlap with any row that has already been seeded. This is especially handy in triangular fields, on curved or irregular shaped headlands.

Præcisionslandbrug

Præcisionslandbrug

Lavet til smart, effektivt og nemt landbrug

IsoMatch GEOCONTROL er et avanceret software-program inden for IsoMatch Tellus og IsoMatch Tellus GO+, der hjælper dig med at styre alle ISOBUS kompatible Kverneland Group maskiner såsom sprøjter, spredere og såmaskiner! Kombineret med en GPS-modtager opfylder den fremtidens behov med hensyn til nemt, smart og effektivt landbrug!

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 2 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus and IsoMatch Tellus GO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

GEOSEED increases the yields of row crops and ensures maximum efficiency. Seeds are placed perfectly in line and in relation to each other.

GEOSEED is offered in two different levels:

GEOSEED Level 1 is the synchronization in the machines working width. This improves the distribution of seeds up to perfection in parallel or diamond pattern: Positive effects are the best use of nutrients, water and sun. Also the wind and water erosion is decreased.

GEOSEED Level 2 is the synchronization in the whole field. This is the necessary requirement for interrow cultivation, also across the seeding direction. GEOSEED is the only system in the world, that makes this mechanic weeds control possible!

Teknisk specifikation

Teknisk specifikation

Download brochure| Model | Optima RS | Optima RS | Optima RS | Optima RS | Optima RS | |

|---|---|---|---|---|---|---|

| Rammetype | Fast | Fast | Fast | Fast | Fast | |

| Arbejdsbredde (m) | 6.10 | 6.80 | 7.60 | 8.30 | 9.30 | |

| Antal standard-/tandemrækker til såning | 8 - 12 | 8- 16 | 12 | 12 - 18 | 12 - 18 | |

| Rækkebredde Standard / Tandemrække (cm) | 45-80 | 35-80 | 65 | 45-70 | 50-80 | |

| Antal rækker med HD-II-såning | 8 - 12 | 8- 16 | 12 | 12 - 18 | 12 - 18 | |

| Rækkebredde HD-II-rækker (cm) | 45-80 | 35-80 | 65 | 45-70 | 50-80 | |

| Transportbredde (m) | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | |

| Mekanisk drev af række | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| e-drive II, klar til GEOSEED® | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Ventilator drev 1000rpm | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Blæserdrev 800 rpm | Standard | Standard | Standard | Standard | Standard | |

| Hydraulisk blæserdrev | Tilvalg | Tilvalg | Valgmulighed | Valgmulighed | Valgmulighed | |

| Forbindelse | KAT III / KAT IV N | KAT III / KAT IV N | KAT III / KAT IV N | KAT III / KAT IV N | KAT III / KAT IV N | |

| Dæk 7.00-12AS | Tilvalg | Valgmulighed | Valgmulighed | Mulighed | Valgmulighed | |

| Dæk 26x12.00STG | Standard | Standard | Standard | Standard | Standard | |

| Hydraulisk betjent sporskriver | Standard | Standard | Standard | Standard | Standard | |

| Hydraulisk rammeballastsæt | Tilvalg | Mulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Monteret gødningsspreder | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Maksimalt antal rækker med monteret gødningsspreder | 18 | 18 | 18 | 18 | 18 | |

| Mekanisk drev til gødningsspreder | Standard | Standard | Standard | Standard | Standard | |

| Elektrohydraulisk drev til gødningsspreder | Tilvalg | Tilvalg | Tilvalg | Valgmulighed | Valgmulighed | |

| Gødningstankens kapacitet i liter | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | |

| Antal rækker med frontbunker f-drill / iXtra LiFe | 8 - 12 | 8- 16 | 12 | 12 - 18 | 12 - 18 | |

| Mikrogranulat-applikator mikroboremaskine | Valgmulighed | Valgmulighed | Valgmulighed | Mulighed | Valgmulighed |

Teknisk specifikation

Teknisk specifikation

Download brochureArbejdsbredde (m) |

6.1 |

6.8 |

7.6 |

8.3 |

9.3 |

Antal rækker |

8 - 12 |

8 - 16 |

12 - 16 |

12 - 18 |

12 - 18 |

Rækkeafstand (cm) |

45 - 80 |

35 - 80 |

65 |

45 - 70 |

50 - 80 |

IsoMatch Tellus GO+

IsoMatch Tellus GO+

IsoMatch InLine

IsoMatch InLine

IsoMatch Global 2

IsoMatch Global 2

IsoMatch MultiEye

IsoMatch MultiEye