Unicorn rigid

PRÆCIS SEPERATION MED EN YDERST PRÆCIS PLACERING

Kverneland Unicorn e-drive II er den mekaniske præcisionssåmaskine med det indvendigt fyldte såhjerte til konventionel såning eller mulchsåning med elektrisk drev og opto-elektronisk overvågning af frøplaceringen.

Beskrivelse

Kverneland Unicorn er designet til professionel præcisionssåning. En elektrisk drevet rækkeenhed med mulchudstyr er standard. Selv under de vanskeligste forhold garanterer parallelogrammonteringen af såenhederne en præcis dybdekontrol.

Unicorn sikrer perfekt såplacering under konventionelle og mulchforhold. Med e-drive II drives hver såenhed elektrisk individuelt. Såafstanden kan justeres trinløst undervejs og kan slukkes individuelt. Unicorn er klar til GEOSEED og GEOCONTROL. Overlappende såning på foragre hører fortiden til, og en synkroniseret såning på linje, men også på tværs af hele marken er mulig.

Højdepunkter

- Uendelig justering af såafstande fra 12,5 til 25 cm, hvilket optimerer frøbestandene til jordtypen inden for den samme mark fra traktorkabinen.

- Multi-valg integrerede systemer til sporing og markering før fremspiring (ekstraudstyr).

- Mulighed for at øge plantebestanden i rækkerne ved siden af sporskifterne.

- Opto-elektronisk styring til frøtælling som standard.

- Individuelle såenheder kan slukkes. Ideelt f.eks. ved såning i hjørnet af uhensigtsmæssigt formede marker.

- Sikkerhed gennem konstant kontrol: elektronikken overvåger permanent alle driftsfunktioner for hver såenhed og viser konstant "realtidsdata" på terminalen i kabinen.

- ISOBUS Intelligence med Unicorn e-drive II

Funktioner

Funktioner

The rigid end-tow toolbars are available in working widths of 3m, 6m, 9m and 12m. The convenient and time saving parallel hydraulic folding is available in 6 m and 9 m toolbar versions. The transport width of all Unicorn models is a maximum of 3 metres.

The hydraulic, parallel folding mechanism allows UNICORN to be easily folded for transport on public roads. Alternatively, there is a lengthways towing facility available for the rigid 12, 18 and 24 row frames. Support or drive wheels on the mid and outer sections provide optimum ground contour following characteristics.

The sowing units – like the whole machine – are modular in design.

The basic element always remains the same and the equipment can be varied according to individual requirements. For mulch seeding, the front Farmflex wheel is simply replaced with a double cutting disc equipped with side zero pressure tyres. The trailing coulter draws a clean seed furrow for precise seed placement.

The Unicorn sowing elements are equipped with the V-press wheel as standard. The zero pressure rubber tyres do not allow soil to stick and provide excellent operation. The seed is covered with loose soil by adjustable coverer. The amount of covering soil is similar to that of the sowing depth ideal for wet and loamy soils.

Optional finger press wheels are recommended for heavy dry soil and soils susceptible to late frost. The seed is covered with loose soil by the adjustable coverer. The covering soil is lower than the sowing depth. A "micro climate" protects the germinated plant.

UNICORN operates as an internally filled drill, with chamber wheel speeds, which correspond to the normal sowing speed in practice. The adjusted chamber speed of the bearing borne chamber wheel minimises bounce and roll impulses, thus increasing the precision of seed placement. Guaranteed filling of each individual cell: The cell wheel internal filling principle for precise seed placement

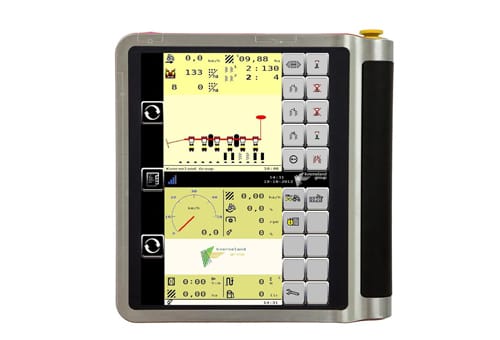

Electronic drive for highest precision. Complete control and monitoring of the machine from the tractor cab in accordance with ISOBUS standard.

The latest Terminal universal ISOBUS terminal – IsoMatch Tellus PRO offering two ISOBUS interfaces in one terminal, the ISOBUS shortcut button and a touch screen display.

- Two ISOBUS screens at a glance

- Integrated tractor ECU programme

- RS-232 connection for a GPS receiver or other external sources

- Option to connect up to 4 cameras

- Multifunctional, ergonomic, user-friendly design

The Tellus GO+ is the cost efficient alternative for ISOBUS compatible machines of the Kverneland Group.

IsoMatch GEOCONTROL - Cost saving with immediate payback

Seeding with GPS and GEOCONTROL in combination with an electric driven precision drill is a major step towards precision and cost saving. These machines are all equipped with ISOBUS technology which with the help of the IsoMatch Tellus terminal, can be easily controlled.

Each electric driven seeding element, in combination with GPS and GEOCONTROL, is automatically switched on or off in exactly the right place, ensuring there is no overlap with any row that has already been seeded. This is especially handy in triangular fields, on curved or irregular shaped headlands.

For further information regarding our iM FARMING concept go to https://ien.kverneland.com/iM-FARMING

GEOSEED - Precision at high end

GEOSEED is offered in two different levels:

GEOSEED Level 1 is the synchronization in the machines working width. This improves the distribution of seeds up to perfection in parallel or diamond pattern: Positive effects are the best use of nutrients, water and sun. Also the wind and water erosion is decreased.

GEOSEED Level 2 is the synchronization in the whole field. This is the necessary requirement for interrow cultivation, also across the seeding direction. GEOSEED is the only system in the world that makes this mechanical weed control possible!

The hoppers, made of special grade plastics, have a capacity of 35 litres.

They are mounted according to the working width with 2 or 3 outlets per unit.

Metering wheels of different sizes and materials are available to suit the application requirements of most types of micro-granule.

Teknisk specifikation

Teknisk specifikation

Download brochure| Model | Unicorn | Unicorn | Unicorn | Unicorn | |

|---|---|---|---|---|---|

| Ramme | Fast | Fast | Fast | Fast | |

| Arbejdsbredde (m) | 3.0 | 6.0 | 9.0 | 12.0 | |

| Antal rækker | 6 | 12 | 18 | 24 | |

| Rækkebredde (cm) | 45/50 | 45/50 | 45/50 | 45/50 | |

| Transportbredde (m) | 3.0 | 3.0 2) | 3.0 2) | 3.0 2) | |

| Vægt for basisversion (kg) | 400 | 910 | 1,75 | 2,8 | |

| e-drive II, forberedt til GEOSEED® -system | Standard | Standard | Standard | Standard | |

| IsoMatch Tellus Pro | Valgmulighed | Mulighed | Mulighed | Valgmulighed | |

| IsoMatch Tellus Go+ | Valgmulighed | Valgmulighed | Option | Option | |

| Radar | Standard | Standard | Standard | Standard | |

| Forbindelse | CAT. II | CAT. II | CAT. III | CAT. III | |

| Dæk 5.00x15 | Standard | Standard | Standard | Standard | |

| Hyraulisk betjente sporafmærkningsarme | Standard | Standard | Standard | Standard | |

| Markører før fremspiring | Valgmulighed | Mulighed 1) | Valgmulighed 1) | Valgmulighed 1) | |

| Vejbelysningssæt | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Sporudrydder (2x2 tænder) | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Ballastsæt med hydr. ramme | Valgmulighed | Valgmulighed | - | - | |

| Transportanordning i længderetningen | - | Valgmulighed | Tilvalg | Valgmulighed | |

| Mikrogranulat-applikator | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Volumen af mikrogranulatbeholder (l) | 35 | 35 | 35 | 35 | |

| Antal mikrogranulatbeholdere | 2 | 4 | 6 | 8 |

1) Risiko for kollision af præ-nødmarkør og transportanordning i længderetningen

2) Transportanordning i længderetningen

Teknisk specifikation

Teknisk specifikation

Download brochureModel |

Working width (m) |

Hopper capacity |

Weight (kg) |

Unicorn |

3.0 /6.0/9.0/12.0 |

9 |

400 – 3500 |

1) Risiko for kollision af præ-nødmarkør og transportanordning i længderetningen

2) Transportanordning i længderetningen