ts-drill

Kverneland tandsåmaskine - det omkostningseffektive alternativ.

Kverneland tandsåmaskine ts-drill er designet til at arbejde under ekstreme forhold, dvs. i tør, stenet eller våd jord. Den er etableret i konventionel jordbearbejdning efter ploven og er også perfekt til reduceret jordbearbejdning. Der findes lige såspidser til at opfylde de forskellige krav

Højdepunkter

- Passer til konventionelle og bevarende jordbearbejdningssystemer

- Klar til ekstreme forhold

- Fremragende jordbundsforfølgning

- Brugervenlig med fremragende overblik

- Tæt tyngdepunkt for at spare brændstof

Beskrivelse

Kverneland ts-drill udfører kultivering og såning i én arbejdsgang. De 5 rækker passive redskaber er indstillet i forskudt konfiguration og muliggør drift ved høj arbejdshastighed. Den store beholderkapacitet på 1700 liter (1350 liter plus 350 liter udvidelse) reducerer indstillingstiden. På grund af den optimerede placering af beholderen er tyngdepunktet tæt på traktoren.

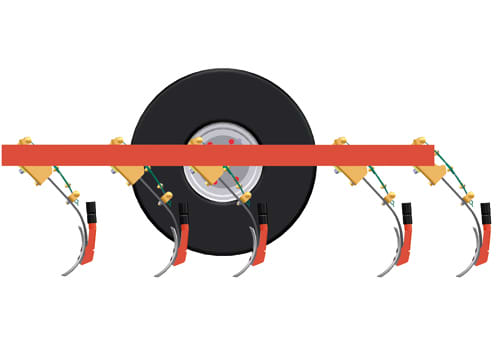

I en enkelt overkørsel tager de automatisk indstillede tænder sig af jordbearbejdning og såning, hvilket igen reducerer jordkomprimering og samtidig sparer brændstof og tid. På grund af de flydende vingesektioner på ts-drill med 5,00 m og 6,00 m arbejdsbredde fungerer ts-drill fint på skråninger eller ujævnt terræn. Landhjulenes centrale placering i hovedrammen tilpasser sig perfekt til jordkonturerne og sikrer dermed en jævn dybdekontrol.

Højdepunkter

- Klar til konventionelle og bevaringsbaserede jordbearbejdningssystemer

- Klar til ekstreme forhold som fugtig jord eller stenede jorde

- Pålidelig præstation takket være velafprøvede ts-drill tænder af højkvalitetsfjederstål & Kverneland bladfjeder automatisk reset overbelastningsbeskyttelse

- Udmærket jordoverfladebehandling takket være hjulene monteret i midten

- Bedrivervenlig med fremragende overblik

- Komplet styring af maskinerne fra traktorkabinen under kørsel

- Miljøvenlig med et tæt tyngdepunkt, der sparer brændstof

Funktioner

Funktioner

- The intelligent arrangement of the seeding tines over five rows allows the ts-drill to place the seeds accurately into the seedbed, even in conditions with high amounts of crop residues. The symmetrical distribution of the rear row of tines ensures excellent seed depth and levelling. The ts-drill can be ordered with tine spacings of 12.5 or 15cm.

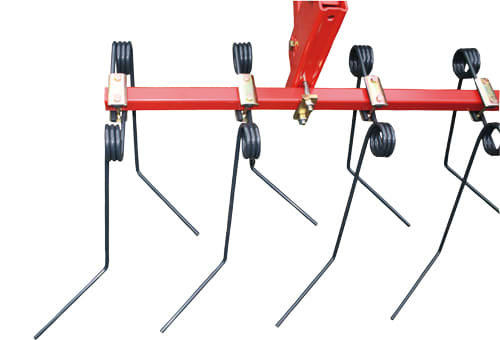

- The seeding tines of the ts-drill are made of high quality spring steel fitted with the Kverneland leaf-spring autoreset overload protection. To ensure the free flow of crop residues through the machine, the tines are arranged in an off-set configuration over five rows.

- The special design of the tines reduce the tractor power requirement and ensure uniform seed depth placement. Also in extremely humid and sticky soils, the ts-drill ensures perfect seeding results.

- Tines in front of the landwheel ― stable running under all conditions

- A tine in front of each landwheel levels the soil and ensures an even and steady running of the ts-drill - a prerequisite for the depth control of the seed placement with tine seeders. Due to the new design of the ts-drill, seeding can be carried out in a crossways direction to the previous cultivation operations.

Equipped with the largest profile wheels of all machines in its class (11.5/80-15.3 10PR), the ts-drill offers significant advantages. The large diameter wheels of the ts-drill run smoothly and easily. The tyre pressure (approximately one bar) ensures the “footprint” of the machine being significantly reduced. Deep wheelings are avoided whilst the seed bed is protected against compaction.

The seeding depth is adjusted, without the need of any tools by using spacers on the wheels mounted in the centre of the main frame. This guarantees that the ts-drill will adapt perfectly to the ground contours and the sowing depth is simply more precise.

- Effective seed covering after sowing is ensured by the twin row precision following harrow section as standard equipment.

- The special design of the tines allows even high quantities of damp plant residues to pass through the harrow without blocking.

- The harrow pressure and its aggressiveness can be adjusted via the spring pressure adjustment and the angle of the harrow bar.

- As option the ts-drill can be equipped with a one-row V-harrow and press wheels. This offers the possibility of applying additional pressure. If the seed press wheels are not required due to very humid conditions, they can be completely lifted.

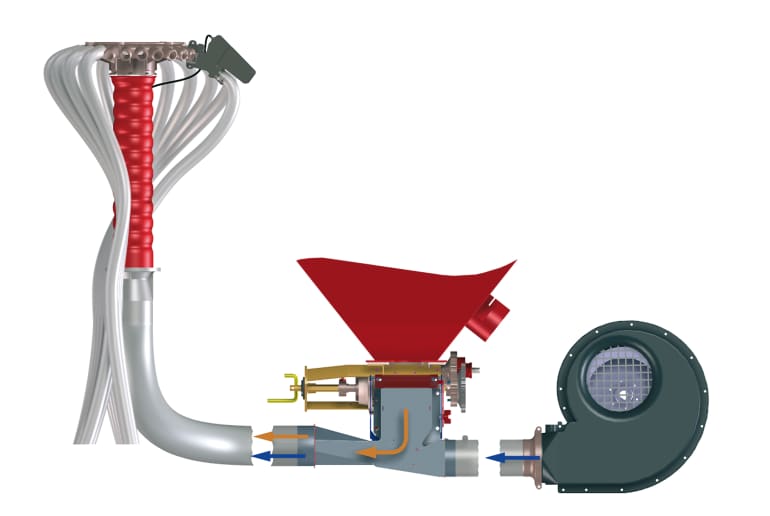

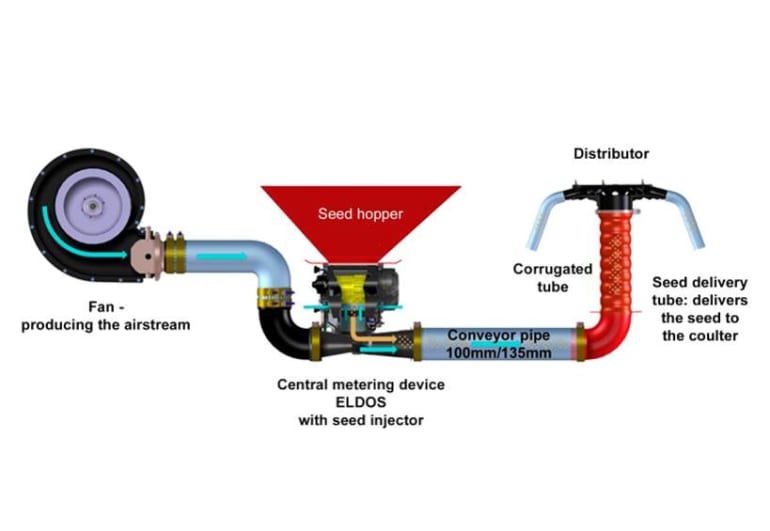

- The central, totally enclosed cell wheel of the metering device accurately measures the required volume of seed and discharges it into the venturi cone where it is mixed with the air stream and then conveyed through the diffuser tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- Apart from the Signus, the pneumatic seed drills can be equipped with the Tellus GO and the IsoMatch Tellus PRO.

- IsoMatch Tellus PRO– the next generation universal ISOBUS Terminal

- Two ISOBUS interfaces in one terminal

- Multifunctional ergonomic design

- ISOBUS Shortcut Button (ICB)

- The IsoMatch Tellus PRO is the first ISOBUS terminal in the world with the capability to operate two different (machine) screens through one terminal, without the need to constantly toggle between screens.

- Via the ISOBUS connection, IsoMatch Tellus PRO automatically identifies the job control unit, which is located on the machine

For the electronic control of the ts-drill, a whole range of steering systems is available

Focus 3

Focus 3 is the new terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about ha, km/h monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

IsoMatch Tellus GO

The multifunctional one-screen terminal has been developed for fast and simple control of all ISOBUS implements, giving the farmer a ‘customer made’ experience as it suits all needs for plain and efficient handling of farming machinery and tasks. IsoMatch Tellus GO is the farmer’s first step into Precision Farming. With the easy to use application, IsoMatch GEOCONTROL, it is possible to boost efficiency and save time and costs. The application includes Manual Guidance, Section Control and Variable Rate.

IsoMatch Tellus

- Two ISOBUS interfaces in one terminal

- Multifunctional ergonomic design

- ISOBUS Shortcut Button (ICB)

The IsoMatch Tellus is the first ISOBUS terminal in the world with the capability to operate two different (machine) screens through one terminal, without the need to constantly toggle between screens. Via the ISOBUS connection, IsoMatch Tellus automatically identifies the job control unit, which is located on the machine.

- The new metering device is electric driven by e-com and is fully ISOBUS compatible.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Four standard rotors are delivered for fine and large seeds or fertiliser.

- A fifth rotor is offered as an option for maize, sunflowers and greening seeds.

- The exchange of the rotors is quick and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

Præcisionslandbrug

Præcisionslandbrug

Lavet til smart, effektivt og nemt landbrug

IsoMatch GEOCONTROL er et avanceret software-program inden for IsoMatch Tellus og IsoMatch Tellus GO+, der hjælper dig med at styre alle ISOBUS kompatible Kverneland Group maskiner såsom sprøjter, spredere og såmaskiner! Kombineret med en GPS-modtager opfylder den fremtidens behov med hensyn til nemt, smart og effektivt landbrug!

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 2 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus and IsoMatch Tellus GO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

Teknisk specifikation

Teknisk specifikation

Download brochure| Model | ts-drill 4800 | ts-drill 5000 | ts-drill 5600 | ts-drill 6000 | |

|---|---|---|---|---|---|

| Arbejdsbredde (m) | 4.80 | 5.00 | 5.60 | 6.00 | |

| Transportbredde (m) | 3 | 3 | 3 | 3 | |

| Antal skær (12,5 cm afstand) | 38 | 40 | - | 48 | |

| Antal skær (15,0 cm afstand) | 32 | - | 40 | 40 | |

| Min. effektbehov (HP/KW) | 120 / 88 | 125 / 92 | 130 / 96 | 130 / 96 | |

| Vægt (kg) | 1,805 | 1,850 | 1,930 | 1,980 | |

| Kapacitet af beholder (l) | 1,350 | 1,350 | 1,350 | 1,350 | |

| Forlængelse af beholder (max. 1700 l) (l) | Tilvalg (350 l) | Tilvalg (350 l) | Tilvalg (350 l) | Tilvalg (350 l) | |

| Dæksel til beholder plus gastryksregulator | Standard | Standard | Standard | Standard | |

| Hurtig tømningsskakt | Standard | Standard | Standard | Standard | |

| Sensor til lavt niveau | Standard | Standard | Standard | Standard | |

| Belysningsbunker indvendigt | Tilvalg | Tilvalg | Valgmulighed | Valgmulighed | |

| Mekanisk blæserdrev | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Hydraulisk blæserdrev | Standard | Standard | Standard | Standard | |

| Kontrol af ventilatorens hastighed | Standard | Standard | Standard | Standard | |

| ELDOS elektrisk måleanordning inkl. 5 rotorer | Standard | Standard | Standard | Standard | |

| Kontrol af doseringsanordning | Standard | Standard | Standard | Standard | |

| Justering af udsædsmængde | Standard | Standard | Standard | Standard | |

| Udsædsmængde med 15 km/t (min. - max.) (kg/ha) | 1-400 | 1-400 | 1-400 | 1-400 | |

| Sporskiftesystem med e-bas eller e-com eletronisk styring | Tilvalg | Tilvalg | Tilbehør | Tilbehør | |

| Afspærringsventiler til sporskifter | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Markør før fremspiring | Valgmulighed | Mulighed | Valgmulighed | Mulighed | |

| Halvbreddeafbrydelse | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| Radarhastighedssensor | Standard | Standard | Standard | Standard | |

| Kalibreringssæt | Standard | Standard | Standard | Standard |

Teknisk specifikation

Teknisk specifikation

Download brochureWorking width |

Hopper capacity |

Weight |

|

ts-drill |

4 / 4.8 / 5.0 / 5.6 / 6.0 |

1200 |

1630 - 1980 |

IsoMatch Tellus GO+

IsoMatch Tellus GO+

IsoMatch InLine

IsoMatch InLine

IsoMatch Global 2

IsoMatch Global 2

IsoMatch MultiEye

IsoMatch MultiEye