Kverneland 6500F

Højtydende pressere med fast kammer

PowerMax fastballekammer med fuld valse og en ballediameter på 1,25 m

Højdepunkter

2.3m extra wide pick-up for increased intake speeds ChopFeed -15 knife pre-chopping system and PowerFeed rotor PowerMax bale chamber with 18 ribbed profile rollers Patented PowerBind net system Intuitive control with the Focus 3 & ISOBUS terminalBeskrivelse

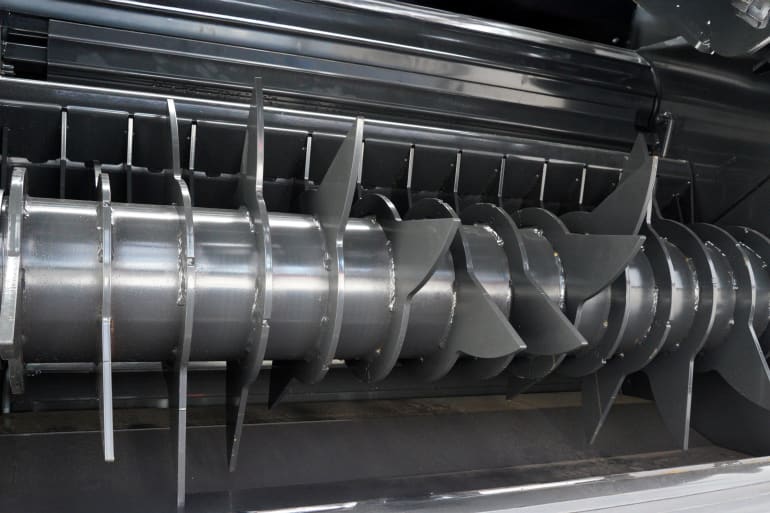

Kverneland 6500F er en specialballepresser til tung ensilage. Pressekammeret består af 18 profilerede valser med ribber, som sikrer maksimal balletæthed og fremragende ballerotation under alle forhold. Samtidig holdes effektbehovet på et minimum, hvilket giver en mere effektiv drift.

Højdepunkter

- 2,3 m ekstra bred lavprofil pick-up med valseafgrødepresse giver ren riveydelse og øget indtagshastighed.

- SuperCut 15-knivs forskæringssystem og PowerFeed-rotor giver suveræn indføringsevne i alle afgrøder.

- Parallelogram Drop Floor-system med optimeret profil for jævnere afgrødeflow og øget frihøjde.

- Patenteret PowerBind-netsystem til hurtig og pålidelig netbinding.

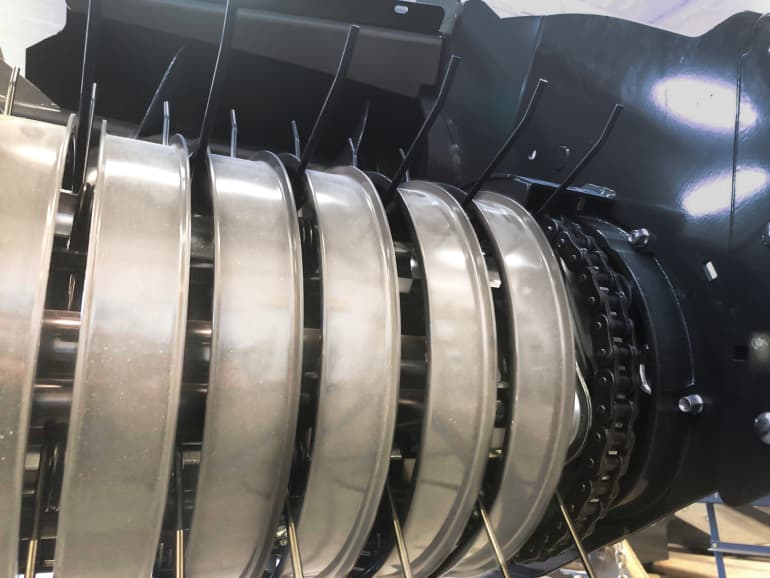

- PowerMax-ballekammer med 18 ribbeprofilvalser, der er designet til våd ensilage og giver velformede baller med høj tæthed.

- Enkel og intuitiv styring med Focus 3-terminalen og valgfri Isobus-konfiguration.

Funktioner

Extra-wide 2.3m pick-up, designated ‘XL+’ incorporates an extensive series of upgrades:

- Equipped with five tine bars with 32 tines per bar

- Each tine bar is supported by four ball bearings along its length

- Twin easy-access cam tracks located at both ends of the pick-up

- Large diameter roller crop press for increased intake speeds

- Innovative inboard driveline design for reduced transport width

ChopFeed 15 Chopping system

ChopFeed 15 knife pre-chopping system provides higher efficiency and improved crop flow into the baler. Special profiled knives have been developed in a consistent chop length with a low power requirement. With a chop length of 70mm, it is the ideal solution for producing tight, dense bales, which result in improved fermentation, with the further benefit of easier feeding out of bales and less wastage.

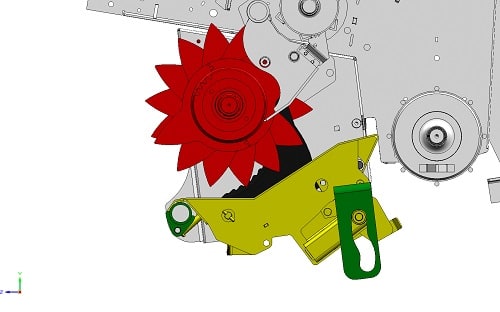

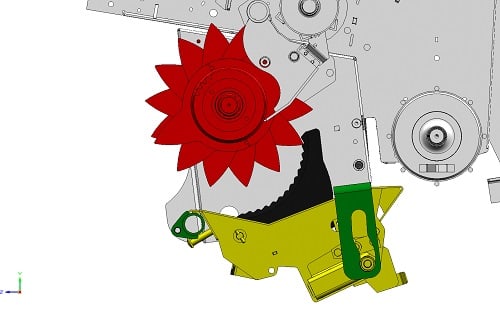

Individual Knife Protection

On the ChopFeed 15, each knife is individually spring protected against foreign obstacles, giving a higher level of protection than systems that protect only the complete knife bank.

New PowerFeed Rotor Intake

Truly impressive intake capacity can be achieved with the new PowerFeed rotor intake system - efficiently handling all crop types, whatever the conditions. Massive intake rotor diameter provides the capacity to cope with the most challenging harvest conditions.

The SuperCut 15 intake system is equipped with the super effective Parallelogram drop floor system, which brings faster and easier clearing of blockages. The system not only lowers the rear edge of the drop floor as per traditional systems but also lowers the front section of the floor, where a blockage is more likely to occur.

The Kverneland 6500F is the specialist baler for heavy silage conditions. The PowerMax bale chamber incorporates 18 heavy duty rollers arranged in a perfect circle for maximum bale rotation capability in all conditions. This is the ideal solution for producing well shaped and dense bales.

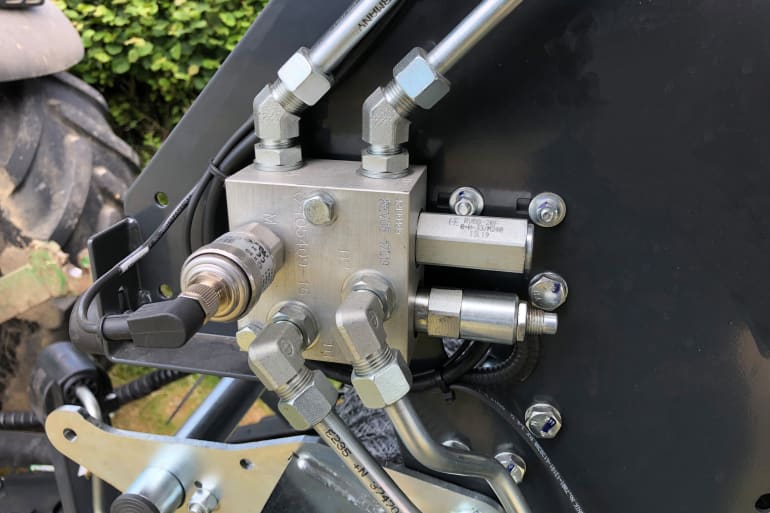

Perfect Bale Formation

Production of consistent, high density bales in both wet and dry material is assured. Two rollers in the lower section of the main bale chamber spread the load, reducing stress and increasing working lifetime. For ultimate flexibility and ease of operation bale density is hydraulically controlled and continuously monitored electronically. Density level can be precisely tailored from the comfort of the tractor cab according to prevailing crop conditions.

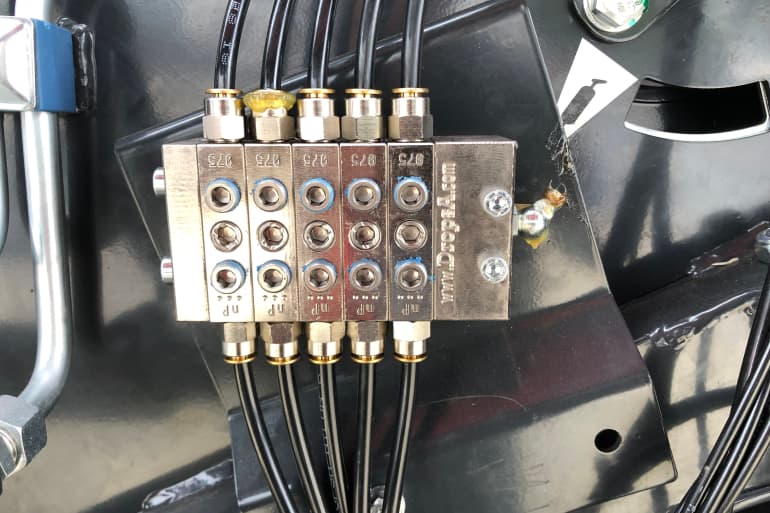

Kverneland 6500F is equipped with the patented front mounted PowerBind net system. PowerBind eliminates troublesome feed rollers and has market leading cycle time.

The net is continuously retained in the PowerBind injection arm. When the bale is 90% complete the arm moves forward ready for the net injection.

When the bale is 100% complete net is fed directly onto the bale in a flat movement angle keeping the net tight at all times, providing accurate and extremely reliable net injection. PowerBind gives you the confidence of doing a professional job, without influence from wind or crop build-up.

Low Net Loading Height

PowerBind offers very low loading height for maximum convenience and time-saving. To replace the empty roll just swing out the shaft and slide on a new roll.

TIM (Tractor Implement Management)

TIM is a cross-product and cross-manufacturer ISOBUS solution for the agricultural machinery industry whereby the implement is able to control certain tractor functions. It enables two-way communication between tractors and implements, allowing both machines to work in perfect harmony. As well as increasing efficiency, the possibility of human error due to fatigue is also greatly reduced.

TIM technology has the advantage of significantly increasing driver comfort by automatically performing many of the repetitive actions of the baling process. The cost aspect is another factor to bear in mind. Highly efficient use of TIM-equipped baler results in lower costs for parts that wear out.

- TIM system as optional equipment

- TIM takes most of the work off the operator's hands when baling

- Significant increase in comfort for the operator, as endless work steps are saved

- Reduced operator fatigue and faster completion of work while maintaining high bale quality

- High user-friendliness of the TIM system, which even regularly changing operators can quickly master

Focus 3 Control

Kverneland 6500F is standard equipped with the Focus 3 terminal. All important settings are made from the comfort of the tractor seat, allowing on the move adjustment and a comfortable working environment.

Focus 3 is designed for easy operation with the following functions controlled from the terminal:

- Bale density adjustment

- Net quantity adjustment

- Tying information during the binding cycle

- Selection of manual or automatic binding

- Five daily bale counters & total bale counter

- Selection of knives, drop floor or pickup raise/lower function

Techno-Pack has been developed to offer professional farmers and contractors the optimum solution in terms of crop harvesting management. The moisture level of crop entering the bale chamber during the baling process is continuously measured and displayed on the baler terminal. Sensor plates are mounted in the lower part of the bale chamber, from which the system calculates the percentage of moisture inside the bale. The system is able to detect moisture levels up to 50% allowing the driver to decide at any time if crops such as hay or straw are fit to bale - your assurance of always preserving the best possible forage quality.

ChopFeed 15 Chopping system

The ChopFeed 15 knife pre-chopping system enhances operational efficiency and ensures smoother crop flow into the baler. Its specially profiled knives are designed to deliver a consistent chop length with minimal power usage. With a chop length of 70mm, it is the perfect solution for creating tight, dense bales. These bales improve fermentation, offer easier feeding out, and minimize wastage.

Individual Knife Protection

Each knife in the ChopFeed 15 is individually spring-protected against foreign objects, providing superior protection compared to systems that only shield the entire knife bank. This innovative design ensures greater durability and reliability.

PowerFeed Rotor Intake

The PowerFeed Rotor Intake system is designed to deliver impressive intake capacity, effortlessly handling all crop types, no matter the conditions. Its large intake rotor diameter ensures the system can manage even the toughest harvest conditions with ease.

The ChopFeed 15 and PowerFeed intakes system feature the highly efficient Vicon Parallelogram drop floor system, designed for quicker and easier blockage clearance. Unlike traditional systems that only lower the rear edge, this innovative design also lowers the front section of the floor, where blockages are more likely to occur, ensuring faster, more effective clearing.

Kverneland 6500F eatures the patented front-mounted PowerBind net system, eliminating the need for troublesome feed rollers. With its market-leading cycle time, PowerBind ensures faster, more efficient baling, making your operation smoother and more reliable.

The PowerBind net system continuously retains the net in the injection arm. As the bale nears completion (90%), the arm moves forward, preparing for net injection. Once the bale is fully formed, the net is fed directly onto the bale at a flat angle, keeping the net tight and ensuring precise, reliable application every time. With PowerBind, you can confidently achieve professional results, unaffected by wind or crop build-up.

Low Net Loading Height

PowerBind features an exceptionally low net loading height, providing maximum convenience and efficiency. Replacing an empty roll is quick and easy—simply swing out the shaft and slide on a new roll.

TIM (Tractor Implement Management)

TIM is an ISOBUS solution that enables cross-product and cross-manufacturer communication between tractors and implements. This system allows for seamless two-way communication, ensuring both machines work in perfect harmony. By automating many repetitive tasks, TIM not only boosts efficiency but also reduces the risk of human error caused by fatigue. This technology enhances driver comfort by taking over numerous manual actions during the baling process.

Cost Efficiency

Another important factor to consider is cost. Utilizing a TIM-equipped baler efficiently can significantly reduce expenses related to wear and tear on parts.

TIM system as optional equipment

TIM simplifies the baling process by taking the majority of the workload off the operator's hands. This results in a significant increase in operator comfort, as it eliminates many repetitive tasks. With reduced fatigue, work can be completed faster while maintaining consistently high bale quality. The TIM system is highly user-friendly, allowing even operators who change frequently to quickly master its functions and seamlessly integrate it into their workflow.

Focus 3 Control

The Focus 3 is built for effortless operation, with all essential functions easily controlled from the terminal. These include:

- Bale density adjustment

- Net quantity adjustment

- Tying information during the binding cycle

- Manual or automatic binding selection

- Five daily bale counters and a total bale counter

- Selection of knives, drop floor, or pickup raise/lower function

With these user-friendly controls, the Focus 3 optimizes your baling process, ensuring greater efficiency and precision at every step.

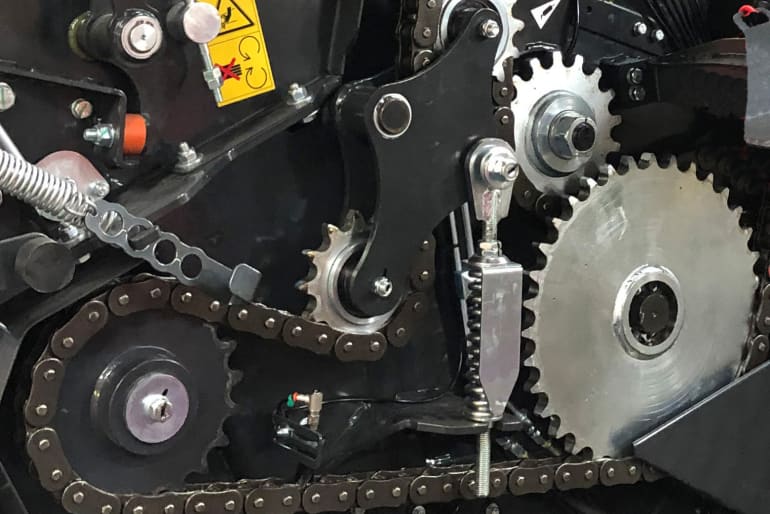

- Bearings are simply greased from four centralised grease banks. Sequential distribution ensures an equal quantity of grease is supplied to each bearing.

- Keeping chains correctly lubricated is crucial for an extended lifetime. FixBale 500 is equipped with an automatic system supplying oil to each individual chain.

The Kverneland 6500F is the ideal baler for heavy silage conditions, built to handle tough tasks with ease. Its PowerMax bale chamber features 18 heavy-duty rollers arranged in a perfect circle, ensuring maximum bale rotation capability in all conditions. This design guarantees the production of well-shaped, dense bales, consistently achieving high density in both wet and dry materials. Two rollers in the lower section of the main bale chamber help distribute the load, reducing stress and extending the baler's lifetime

Adaptable Bale Density

For ultimate flexibility, the bale density is hydraulically controlled and electronically monitored, allowing for precise adjustments from the comfort of the tractor cab. This feature lets you tailor the bale density to suit the prevailing crop conditions for optimal results.

The automatic greasing reduces the daily maintenance and increases the reliability through continuous greasing.

The 2.3m pick-up is packed with advanced upgrades for superior crop handling and durability:

- Five-Tine Bar System – Features 32 tines per bar for optimal crop gathering and efficiency.

- Reinforced Stability – Each tine bar is supported by four ball bearings for smoother operation and extended lifespan.

- Precision Cam Tracks – Twin easy-access cam tracks at both ends ensure seamless performance and maintenance.

- High-Capacity Roller Crop Press – Large diameter design enhances intake speeds for improved efficiency.

- Compact Inboard Driveline – Reduces transport width, offering better maneuverability and ease of transport.

- The one piece integrated input gearbox ensures long life time and requires minimal horsepower.

- Our intake rotor and all bale chamber drives are equipped with heavy-duty 1¼” pitch chains, ensuring durability and high performance.

- Extended service life thanks to the 50mm diameter bearings at both ends on the baler chamber rollers.

Teknisk specifikation

Teknisk specifikation

Download brochure| 6500F PF | 6500F CF15 | ||

|---|---|---|---|

| Ballekammer: | Fuld rulle | Fuld rulle | |

| Ballestørrelse (m): | 1.23 x 1.25 | 1.23 x 1.25 | |

| Indtag: | PowerFeed-rotor | ChopFeed 15 knive | |

| Indbinding: | Net | Net |

Alle ballepressere med variabelt kammer og HD-presseren med fast kammer er kompatible med Tractor Implement Management (TIM) - licens skal købes på https://software.terrako.com + Bale Ramp & TechnoPack er obligatorisk.

Teknisk specifikation

Teknisk specifikation

Download brochureModel |

Bale Diameter |

Intake System |

Binding |

6500F CF15 |

1.23 x 1.22m |

ChopFeed-15 |

Net |

6500F PF |

1.23 x 1.22m |

PowerFeed |

Net |

Alle ballepressere med variabelt kammer og HD-presseren med fast kammer er kompatible med Tractor Implement Management (TIM) - licens skal købes på https://software.terrako.com + Bale Ramp & TechnoPack er obligatorisk.