Kverneland Satio F

Effektiv og omkostningseffektiv såning - med fleksibilitet klar til fremtiden

Kompakt såmaskine til solodrift til små og mellemstore traktorer

Højdepunkter

- Compact & lighweight design - low power requirement

- Flexible - sowing independently from seedbed preparation

- Precise seed placement

- Cost-efficient

- High sowing speeds - large performance

Beskrivelse

Den kompakte solosåmaskine Kverneland Satio F fås med en arbejdsbredde på 5,0 m og 6,0 m. Ved solosåning giver Kverneland Satio ekstra fleksibilitet til også at tilpasse sig ekstreme vejrforhold. Der er kun behov for et lavt effektbehov på grund af et tæt tyngdepunkt. Der kan opnås højere såhastigheder og en høj ydeevne. Frøbeholderen har en stor kapacitet på 1.700 l. Det elektrisk drevne ELDOS doseringssystem (1-400 kg/ha) i e-com eller e-bas version giver maksimal komfort. En radarhastighedssensor registrerer hastigheden for at opretholde den relevante udbringningsmængde. Satio F er fuldt ISOBUS-styret.

CX-II-skærene, med eller uden pressehjul, er fastspændt til skærstangen og giver mulighed for tilpasning til individuelle landbrugssystemer ved at vælge den rigtige rækkeafstand på 12,5 cm eller 25 cm. Såskærstrykket justeres mekanisk eller kan styres hydraulisk fra kabinen. Sådybden justeres centralt via afstandsstykker. Trykhjul understøtter finjusteringen af sådybden og øger kontakten mellem jord og frø for hurtig fremspiring. Integrerede sporudlæggere er standard

Et komplet udvalg af ekstraudstyr som markører til før fremspiring, efterharve med S-tænder, vejlyssæt eller LED-arbejdslygter kan fås til individuelle behov.

Højdepunkter

- Kompakt og let design - lavt strømforbrug

- Mere fleksibel - såning uafhængig af forberedelse af såbedet

- Præcise udsædsmængder - elektrisk drevet ELDOS doseringsenhed

- Præcis placering af såsæden - CX-II såskær med eller uden pressehjul

- Omkostningseffektiv

- Høj ydeevne - hurtigere såhastigheder, stor beholderkapacitet

- ISOBUS-styret

Funktioner

Funktioner

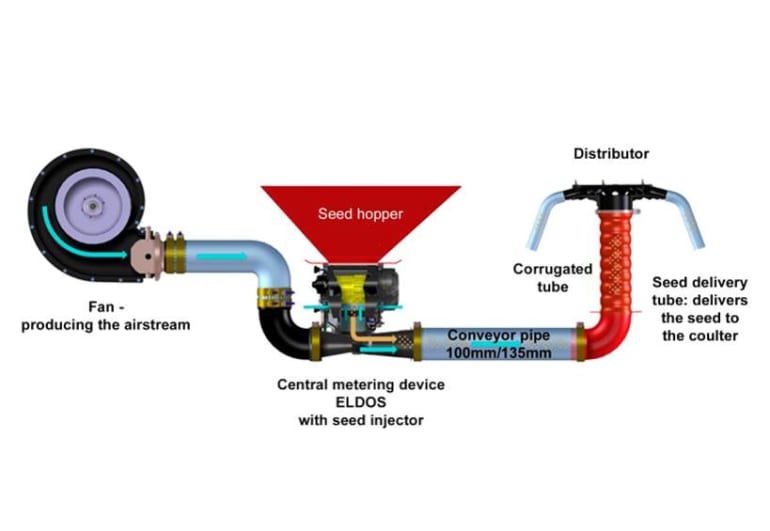

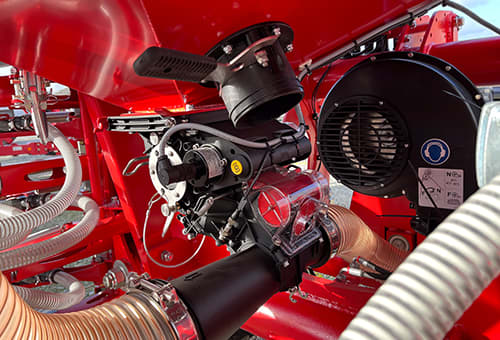

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

- The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement.

- The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

- Due to the combination of the steel disc with a diameter of 325mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

- Up to 50kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface.

- An inter-row coulter spacing of 445mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions.

- The press wheels can be set in fixed, floating of lifted position in order to be able to adapt quickly to changing weather, soil or working conditions.

- The CX-II coulter is also available as light edition without press wheel which reduces the weight and length of the coulterbar. This will allow to operate the seeding combination also with lower lifting capacity of the tractor.

The Satio F is available as e-bas and e-com model. Both models are equipped with the electric ELDOS metering device. The Satio F e-bas is not ISOBUS compatible and the electronic control is ensured by the Focus 3 terminal. The Satio F e-com model on the other hand is fully ISOBUS controlled and can be steered by the Kverneland IsoMatch Tellus GO+, the IsoMatch Tellus PRO or any other terminal.

Focus 3

Focus 3 is the terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about hectare, km/h, monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

IsoMatch Tellus GO+

The multifunctional one-screen terminal has been developed for fast and simple control of all ISOBUS implements, giving the farmer a ‘customer made’ experience as it suits all needs for plain and efficient handling of farming machinery and tasks. IsoMatch Tellus Go+ is the farmer’s first step into Precision Farming. With the easy to use application, IsoMatch GEOCONTROL, it is possible to boost efficiency and save time and costs. The application includes Manual Guidance, Section Control and Variable Rate.

IsoMatch Tellus PRO

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

With this terminal you can work all the way as a PRO. The maximum working range for the task controller IsoMatch GEOCONTROL is increased from 2 km to maximum 10 km from the starting point. Thus even extremely big fields are handled in a full professional way. The new high brightness screen increases operator comfort. Visibility is increased during the day and dimmed to just a glowing display in dark conditions.

- The drill can be ordered with two different row spacings of 12.5cm or 25.0cm according to individual farming systems.

- The CX II coulters are clamped in staggered position over 2 rows by short and longer brackets.

- More clearance means different seed density and micro climate in the crop.

Choice of sowing distance

Sowing distance 12.5cm

- Best distribution for high seed rates

- Rows close quickly

- Reduced weed pressure

- Efficient use of nutrients, water and sun

Sowing distance 25cm

- Optimised micro climate reduces fungal infestation

- Less seeds needed per m² with new type of seeds (hybrid)

- Saving on water resources

- Reduced pulling force requested

- Better clearance in wet conditions

Teknisk specifikation

Teknisk specifikation

Download brochure| Type maskine | Satio 1050 F | Satio 1060 F | ||

|---|---|---|---|---|

| Ramme | Foldbar | Foldbar | ||

| Arbejdsbredde (m) | 5.0 | 6.0 | ||

| Transportbredde (m) | 3.0 | 3.0 | ||

| Beholderkapacitet (l) | 1700 | 1700 | ||

| Skakt til hurtig tømning | Standard | Standard | ||

| Sensor til lavt niveau | Standard | Standard | ||

| Kobling top | CAT II / CAT III | KAT II / KAT III | ||

| Kobling lav | KAT II / KAT III N / KAT III | KAT II / KAT III N / KAT III | ||

| Hjul type | 26x12.00 | 26x12.00 | ||

| Drev 1000 o/min | Standard | Standard | ||

| Drev 540 o/min | Ekstraudstyr | Ekstraudstyr | ||

| Hydraulisk ventilatordrev | Standard | Standard | ||

| ELDOS elektrisk drevet doseringsenhed (nr.) | Standard (1) | Standard (1) | ||

| Radarhastighedssensor | Standard (1) | Standard (1) | ||

| Mikro-måling | Standard | Standard | ||

| e-bas elektronisk (Focus 3) | Standard | standard | ||

| e-com elektronisk (IsoMatch Tellus Pro/Tellus GO+) | Mulighed | Mulighed | ||

| Kontrol af måleenhed | Standard | Standard | ||

| Justering af udsædsmængde | Standard | Standard | ||

| Frømængde (min. - maks.) | 1 - 400 kg/ha | 1 - 400 kg/ha | ||

| Afspærringsventiler til kørespor | Mulighed | Mulighed | ||

| Elektrisk halvbreddeafspærring | Mulighed | Mulighed | ||

| Markør før fremspiring | Mulighed | Mulighed | ||

| Antal såskær 12,5 cm afstand (antal) | Standard (40) | Standard (48) | ||

| Antal skår 25 cm afstand (antal) | Standard (20) | Standard (24) | ||

| CX-II-skær inkl. pressehjul | Standard | Standard | ||

| CX-II-skær med speciel skiveform uden pressehjul | Mulighed | Ekstraudstyr | ||

| CX-II-skærskive Ø (mm) | 325 | 325 | ||

| Pressehjul Ø (mm) | 250 x 42 | 250 x 42 | ||

| Såskærstryk CX-II skiveskær (kg) | 5 - 50 | 5 - 50 | ||

| Mekanisk justering af skærtryk med håndsving | Standard | Standard | ||

| Hydraulisk justering af såskærstryk | Mulighed | Ekstraudstyr | ||

| Mekanisk central indstilling af sådybde | Standard | Standard | ||

| Efterharve med S-tænder (10 mm) | Mulighed | Ekstraudstyr | ||

| Sporudrydder | Standard | Standard | ||

| Værktøjskasse og kalibreringssæt | Standard | standard | ||

| Hydr. sammenklappelig spormarkør med tandskive | Mulighed | Ekstraudstyr | ||

| Ladetrin/platform | Mulighed | Mulighed | ||

| LED arbejdslys | Mulighed | Mulighed | ||

| Sæt til vejbelysning | Ekstraudstyr | Ekstraudstyr | ||

| Oliepåfyldning hydr. ventilator 4400 U/min (l/min) | 30 | 30 | ||

| Min. effektbehov (HP/kW) | 122/90 | 146/108 | ||

| Vægt (kg) med såskær | 1370 - 2160 | 1450 - 2350 |

Teknisk specifikation

Teknisk specifikation

Download brochureModel |

Satio 1050 F |

Satio 1060 F |

Frame |

mounted foldable |

mounted foldable |

Working width (m) |

5.0 |

6.0 |

Transport width (m) |

3.0 |

3.0 |

Hopper capacity (l) |

1700 |

1700 |

ELDOS electric driven metering device (N°) |

Standard (1) |

Standard (1) |

N° of coulters 12.5cm distance (N°) |

40 |

48 |

N° of coulters 25.0cm distance (N°) |

20 |

24 |

Min. power requirement (HP/kW) |

122/90 |

146/108 |

Weight (kg) with coulters |

1370 - 2160 |

1450 - 2350 |