Kverneland 6250

RotaMax fastkammer ballepresser med en ballediameter på 1,25 m

Kverneland 6250 Plus

Beskrivelse

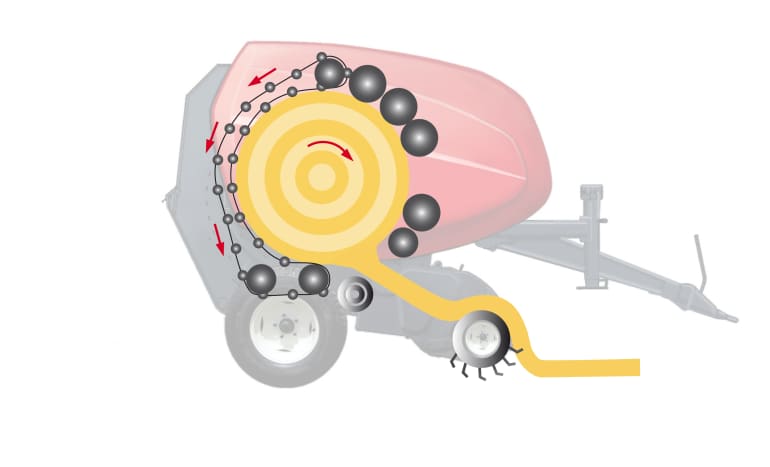

Kverneland 6250 Plus-serien af ballepressere med fast kammer er designet til maksimal fleksibilitet under alle afgrødeforhold. Perfekt formede baller kombineret med langvarig, pålidelig ydeevne sikrer, at Kverneland 6250 Plus-serien vil være en rentabel investering. Kverneland 6250 Plus har et pressekammer, der er designet med fem valser i den forreste del af pressekammeret og kæde og lameller i bagklappen. Denne kombinerede løsning giver fremragende afgrødehåndtering under alle forhold med ensartede baller med høj densitet i både vådt og tørt materiale.

Højdepunkter

- 2.0 eller 2.0

- 2,0 eller 2,20 m arbejdsbredde lavprofil pick-up med lille diameter på valsen for hurtig og effektiv gennemstrømning.

- Fødegaffel, PowerFeed-rotorindtag eller Supercut 14-knivs forskærer

- Parallelogram Drop Floor-system til nem og hurtig frigørelse af blokeret afgrøde.

- Patenteret PowerBind-system til hurtig og pålidelig net- og garnbinding.

- RotaMax-ballekammer - rullesektion foran med kæde- og lamelbagklap til høj balletæthed og god balleform under alle forhold

- Enkel og intuitiv styring med Focus 3-terminalen og valgfri Isobus-konfigurationer.

Funktioner

- The Kverneland 6250 offers a bale chamber designed with 6 rollers at the front and chain and slat at the rear part.

- The combined solution gives excellent crop handling in all conditions with consistent, high density bales in both wet and dry material.

- The chains and slat of the rear section give an early and 100% regular bale rotation and hence faster bale formation leading to denser core of the bale. Even in very dry crops.

- The heavy duty rollers of the front section ensure a well-shaped bale finish and very tight bales.

- The chains in the rear section results in less crop loss compared to a full-roller concept.

- The tail gate has a completely enclosed design to reduce crop loss to a minimum, especially when operating in silage.

- Kverneland Drop Floor enables the operator to clear blockages easily from the tractor cab without any crop loss.

- Drop the floor to free the rotor of blockage, engage the PTO to feed the blockage through and close the floor to continue baling

SuperCut-25

- The SuperCut-25 pre-chopping system offers the ultimate solution for short chop baling with a chop length of 40mm. The short and precise chop provides dense and airtight bales for the best possible silage quality.

- The operator can choose to engage 25, 13, 12, 6 or 0 knives, giving maximum flexibility of operation.

- The SuperCut- 25 knives are fitted with dual action protection against foreign objects. Each knife is individually spring protected and can move in two directions.

SuperCut-14

- The SuperCut-14 knife chopping system provides a fast and efficient flow into the baler. With a chopping length of 70 mm it is the ideal solution for producing tight bales with superb silage quality.

- Each individual knife is spring protected against foreign obstacles. The knife will immediately return to working position once the obstacle has passed.

SuperFeed Rotor Intake for Ultimate Capacity

Truly impressive intake capacity can be achieved with the SuperFeed rotor intake system - handling all crop types with ease, whatever the conditions.

Single or Dual Fork Feeder

- The fork feeder versions are fitted with a cost efficient fork feeder intake system. This system provides direct feed into the bale chamber, and the wide opening allows almost unrestricted intake capacity for fast and efficient bale start.

- In addition the fork feeder gives less vibration and reduced power consumption.

- Dual fork feeder with double feed tines ensures even higher capacity, while still safeguarding fragile crop types.

Kverneland Group Mechatronics has recently launched a new operator terminal, the Focus 3. This terminal is developed for specific implement types and will only be delivered as package for those implements, together with the electronics for balers. The terminal Focus 3 is positioned in the market as an economy solution.

- The Focus 3 terminal is easy to learn and very intuitive, with control terminal with focus on functionality and operating simplicity.

- The Focus 3 terminal is a universal control terminal which can also be used with other implements from the Kverneland Group.

- The Focus 3 terminal gives you full control of all functions from the tractor cab. They are shown on a large, clear digital display.

- The Focus 3 terminal monitors and controls all necessary functions with all relevant parameters are visible at a glance.The control box is also driving the binding automatically without any intervention from the operator.

Easy Loading

- The very low loading height and the very easy threading of the system mean minimum downtime and maximum time baling. Storage for three rolls of net means you don’t have to worry about running out of net when the pressure is really on during long working days.

Twine Tying

- Automatic twine tying with the fast acting double tube system means simultaneous binding of both edges of the bale, keeping binding time to a minimum. Over crossing of twines in the centre of the bale provides no loose ends at the end of the binding cycle.

- The system is fully user programmable to make sure you make the best looking bales in all crop conditions.

New PowerBind Net Wrap

- The New Fix chamber baler is equipped with the patented new PowerBind net wrap system. PowerBind provides positive and reliable injection of net in all crop conditions, while also eliminating potentially troublesome feed rollers.Additionally the PowerBind provides one of the fastest net wrap actions available. This means minimum downtime and maximum time baling

- Net is fed right to the outside of the bale, with a specially widened entry channel, which also allows extra wide net types to be utilized if required.

- The simple net wrap system allows the net to extend past the edge of the bale. The 1.30m net is wider than the baling chamber, so that the net can be pulled over the edge of the 1.20m bale. The result is consistent perfectly shaped and tightly secured bales

Præcisionslandbrug

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

Teknisk specifikation

Teknisk specifikation

Download brochure| 6250 Plus F | 6250 Plus R | 6250 Plus SC14 | ||

|---|---|---|---|---|

| Bale chamber: | Rollers & chain | Rollers & chain | Rollers & chain | |

| Bale size (m): | 1.20 x 1.25 | 1.20 x 1.25 | 1.20 x 1.25 | |

| Intake: | Feeder Fork | PowerFeed rotor | SuperCut-14 | |

| Binding: | Net, Net & Twine | Net, Net & Twine | Net, Net & Twine |

Teknisk specifikation

Teknisk specifikation

Download brochureBale Diameter |

Intake System |

Binding |

|

6250 F |

1.20 x 1.25m |

Fork Feeder |

Net and double Binding |

6225 R |

1.20 x 1.25m |

SuperFeed |

Net and double Binding |

6250 SuperCut-14 |

1.20 x 1.25m |

SuperCut-14 |

Net and double Binding |

IsoMatch Tellus GO+

IsoMatch Tellus GO+