DG II

Effektiv såning med såmaskine med høj kapacitet til høj og præcis frøproduktion.

Den bugserede såmaskine med høj kapacitet opfylder kravet om størst mulig effektivitet og produktion

Højdepunkter

Høj ydeevne og stor kapacitet Active-on-system for overlegen kontrol af sådybde Præcis placering af såsæd ved hjælp af ELDOS- og CD-skær God synlighed og manøvredygtighed Let tilgængelig for indstilling og vedligeholdelseBeskrivelse

Kverneland DG II-såmaskinen kombinerer høj ydeevne, sikker, hurtig transport, nem justering og kort forberedelsestid i én maskine. Med en arbejdsbredde på 9 eller 12 meter og en beholderkapacitet på 6.000 liter er DG II en perfekt højkapacitets såmaskine til udsæd på op til 140 ha på én dag!

Den smalle profil af såskærene med deres let forskudte stålskiver giver nem indtrængning i jorden for den mest præcise frøplacering.Med den løbende justering af sådybde og såskærtryk ved hjælp af Active-on-systemet (op til 80 kg) og den automatiske forlandsstyring. Den højkapacitets-DG II en komfortabel og sikker anvendelse for føreren. Store hjul (800/45 x 26,5) sikrer sikker håndtering på vejen og lavt tryk på jorden.

Højdepunkter

- Høj ydeevne og stor kapacitet

- Overlegen kontrol af sådybden også ved høje arbejdshastigheder ved hjælp af Active-on-systemet

- Stærkt rammedesign for stabilitet og pålidelighed

- Den nyeste såteknologi med ELDOS og CD-såmaskine

- Godt udsyn og god manøvredygtighed

- Kompakt på vejen i transportposition

- Let tilgængelig for indstilling og vedligeholdelse

Funktioner

In order to give sufficient support to the 6000l seed hopper and two-section coulter bar, Kverneland developed a sturdy frame design for the DG-II that distributes the weight of the machine evenly between the carrier axle and the tractor.

The 800/45 x 26.5 wheel equipment ensures safe handling on the road and low pressure on the soil. In the working position the independently mounted toolbars are supported by sensor wheels that ensure accurate tracking and seed depth for the individual coulters during the seeding operation.

Powerful hydraulic cylinders guarantee safe conversion from the transport position to the working position and vice versa!

- ELDOS is electric driven by e-com and is fully ISOBUS compatible.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Four standard rotors are delivered for fine and large seeds or fertiliser.

- A fifth rotor is offered as an option for maize, sunflowers and greening seeds.

- The exchange of the rotors is quick and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

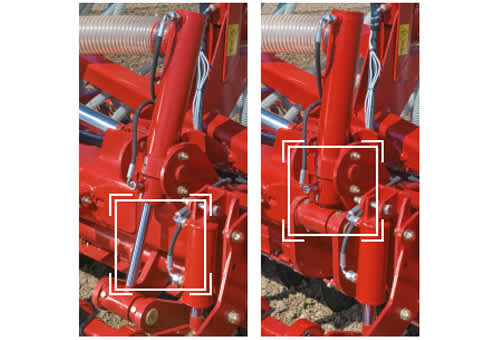

The CD mulch seed coulter consists of two steel discs (Ø410mm) with 12.5cm row spacing. Thanks to its very slim design the soil movement is very little, which leads to a smaller need for pressure to achieve the seeding depth. Thus more of the available coulter pressure of up to 80kg can be led to the press wheels when needed. The coulter pressure can be set infinitely.

Fully integrated maintenance-free disc bearings provide an easy flow of the coulter. The press wheels (Ø 380mm) are made of special rubber which has a self-cleaning effect. So in most conditions no scrapers are required.

The coulter staggering is 175mm. The coulter pressure adjustment is done centrally and can be set infinitely from 0-80kg. The seed depth adjustment is steered centrally via the ISOBUS terminal (series equipment). The two distribution heads are mounted on the coulterbar.

Advantages:

- Extremely narrow profile design – less pressure required for penetration

- Reduced pulling force – due to less soil movement

- Integrated depth guidance and press wheel functionality

- Maintenance free, high performance bearings

With Kverneland's Active-on system, the coulter pressure can be adjusted up to a maximum of 80 kg. The system benefits from the interaction between the coulter pressure and the pressure of the coulter toolbars across the entire width of the machine.

Where coulter pressure is high (retracted cylinder), the pressure on the coulter toolbars is increased. This in turn produces a back pressure for the coulters which results in excellent coulter penetration! With the series e-com model, the pressure can be adjusted to between 0 and 90 bar from the control unit located in the tractor cab.

The Active-on system actively regulates the coulter pressure with the help of individual pressure sensors thus guaranteeing that the pressure set is maintained in order to ensure the precision and consistency of the sowing depth. In order to reduce the load on the toolbar wheels during turning at the headland, the coulter pressure/coulter bar pressure is always neutralised and then automatically increased again to the pre-set value when the coulter bars are lowered again.

Kverneland engages in active, intelligent prevention of wear!

Due to the compact design of the Kverneland DG-II, this large machine generally requires no special authorization for road transport. With a width of 3 metres and a height of 4 metres, its dimensions are within European traffic regulation standards. The machine’e dimensions also allow it to pass through standard bridges and tunnels.

The machine is connected to the tractor via the lower link hitch CAT 3*. The road lights and fixed warning signs are fitted as standard to ensure in combination with the optional dual-circuit air brakes (or hydraulic brake) compliance with traffic regulations and safe movement of the machine on roads.

The machine tows exceptionally well due to the sturdy axles and floatation wheel equipment, it can be authorized to be towed at speeds up to 40 km/h. This results in transport and machine preparation times being reduced. The seeding operation becomes faster and more efficient. The machine’s great manoeuvrability and ease of transport ensures that lower lying fields and small pockets of land can also be reached. For safe parking of the machine a sturdy parking leg is fitted.

* CAT 3, 3N and 4 N lower link hitches, and a hydraulic braking system are available as options..

Præcisionslandbrug

Lavet til smart, effektivt og nemt landbrug

IsoMatch GEOCONTROL er et avanceret software-program inden for IsoMatch Tellus og IsoMatch Tellus GO+, der hjælper dig med at styre alle ISOBUS kompatible Kverneland Group maskiner såsom sprøjter, spredere og såmaskiner! Kombineret med en GPS-modtager opfylder den fremtidens behov med hensyn til nemt, smart og effektivt landbrug!

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 2 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

Teknisk specifikation

Teknisk specifikation

Download brochure| Model | DG II 9000 | DG II 12000 | |

|---|---|---|---|

| Arbejdsbredde (m) | 9.00 | 12.00 | |

| Transportbredde (m) | 3.00 | 3.00 | |

| Transportlængde (m) | 8.55 | 8.55 | |

| Antal doseringsenheder ELDOS® | 2 | 2 | |

| Udsædsmængde med 15 km/t (kg/ha) | 1 - 320 | 1 - 320 | |

| Beholderkapacitet (l) | 6,000 | 6,000 | |

| Påfyldningshøjde (m) | 3.10 | 3.10 | |

| Påkrævet olievolumen | > 110 l/min | > 110 l/min | |

| Enkeltvirkende hydraulikventil + nultryksretur til ventilatordrev | Standard | Standard | |

| 1 x dobbeltvirkende hydraulikventil til maskinstyring | Standard | standard | |

| Strømbehov 12 V > 70 A | Standard | standard | |

| Elektro-hydraulisk indstilling af aflæsning via ISOBUS-terminal | Standard | Standard | |

| Antal CD-skær | 72 | 96 | |

| Skærtryk op til 80 kg (Active-on-system) | Standard | Standard | |

| Pressehjul (Ø 380 x 50 mm) | Standard | Standard | |

| Skraber til pressehjul | Mulighed | Ekstraudstyr | |

| Rækkeafstand (12,5 cm) | Standard | Standard | |

| Elektronisk justering af udsædsmængden med radar | Standard | standard | |

| Fyldeniveausensorer i frøbeholderen (nr.) | Option (2) | Ekstraudstyr (2) | |

| Hydraulisk blæserdrev | Standard | Standard | |

| Sensor til blæserhastighed | Standard | Standard | |

| Overvågning af måleenhed | Standard | Standard | |

| Elektronisk halvbreddeslukning | Standard | Standard | |

| Magnetiske afspærringsventiler (maks. antal) | Option (8) | Option (8) | |

| Kalibreringssæt | Standard | Standard | |

| LED arbejdslys | Mulighed | Ekstraudstyr | |

| Vedligeholdelsesplatform, lyn til vejtransport og inde i beholderen | Standard | Standard | |

| Underledsophæng CAT III (965 mm) | Standard | Standard | |

| Underlift KAT III N (825 mm) | Mulighed | Ekstraudstyr | |

| Sænketrækg KAT IV N (965 mm) | Mulighed | Mulighed | |

| Hydr. clod board | Mulighed | Ekstraudstyr | |

| S-Følgeharve 10 mm | Standard | Standard | |

| Finger-følgeharve 12 mm | Mulighed | Ekstraudstyr | |

| Hydraulisk foldbare spormarkeringsarme med tandede skiver | Mulighed | Ekstraudstyr | |

| Hydr. sporudrydder (2 tænder pr. traktorspor) | Mulighed | Mulighed | |

| Sporerydder (2 tænder pr. hjul på vingesegmentet) | Mulighed | Mulighed | |

| Sporjævner (3 tænder pr. transporthjul DG II) | Mulighed | Mulighed | |

| Transporthjul (mm) | 800/45-26.5 | 800/45-26.5 | |

| Hjul på vingesegmentet (mm) | 31x15.5-15 | 31x15.5-15 | |

| Luft bremse | Mulighed | Mulighed | |

| Hydraulisk bremse | Mulighed | Mulighed | |

| Markør før fremspiring (midtermarkering) | Mulighed | Ekstraudstyr | |

| iM Tellus til ikke-ISOBUS-kompatible traktorer | Mulighed | Mulighed | |

| iM Tellus til ISOBUS-kompatible traktorer | Mulighed | Mulighed | |

| Forvaltning af forager | Standard | Standard | |

| Maks. vejtransporthastighed (km/t) | 40 | 40 | |

| Vægt (kg) (basisudstyr) | 6,850 | 7,660 | |

| Min. effektbehov (HP) | 180 | 230 |

Teknisk specifikation

Teknisk specifikation

Download brochureModel |

DG-II 9000 |

DG-II 12 000 |

Working Width (m) |

9.00 |

12.00 |

Transport Width (m) |

3.00 |

3.00 |

Transport Length (m) |

8.20 |

8.20 |

No. of coulters |

72 |

96 |

Row distance (cm) |

12.5 |

12.5 |

IsoMatch Tellus GO+

IsoMatch Tellus GO+

IsoMatch InLine

IsoMatch InLine

IsoMatch Global 2

IsoMatch Global 2

IsoMatch MultiEye

IsoMatch MultiEye