Kverneland FastBale Premium

Den nye standard inden for presning og indpakning

Non-stop kombination af ballepresser og indpakker med fast kammer

Højdepunkter

- Maskinen er designet med to faste kamre med fuld rulle

- Non-stop presning og indpakning for maksimal produktion

- 2,2 m pick-up og enorm indtagningsrotor med 50 Hardox-tænder

- Et smidigt balleoverførselssystem og højhastighedsviklingssystem

- Kraftig drivlinje med 1000 rpm indtagningsgearkasse

Beskrivelse

Kverneland FastBale repræsenterer et stort skridt fremad inden for rundballepresseteknologi. Non-stop presning og indpakning i en ballepresser med fast kammer er nu en praktisk realitet. Der spares omkring 20 sekunder for hver balle, der laves, sammenlignet med konventionelle stop-start-systemer, og daglige produktivitetsgevinster på over 30 % er hverdagskost. Mindre stress for føreren, mindre slitage på traktorens transmissioner og øget balletæthed på grund af dobbelt komprimering af ballen er blot nogle af fordelene. Med den enorme kapacitet fra 800 mm indtagsrotoren og et innovativt højhastigheds dobbelt satellitindpakningssystem med skånsom ballefrigørelse er det klart, hvorfor FastBale hurtigt er blevet den foretrukne maskine for progressive ensilageproducenter verden over.

Højdepunkter

- Non-Stop FastBale kombipresser eliminerer i sandhed stop og gå-frustrationen ved konventionel rundballepresning. Maskinen er designet med to faste kamre med fuld valse

- .

- 2,2 m pick-up og massiv indtagsrotor med en diameter på 800 mm udstyret med 50 Hardox-tænder, der giver uovertruffen indtagskapacitet

- .

- Et jævnt balleoverførselssystem og et vertikalt indpakningssystem med høj hastighed sikrer højt output og skånsom balleudløsning

- .

- Innovativt indpakningssystem med to satellitter, der roterer om den lodrette akse, hvor ballen understøttes af to drevne valser

- .

- Stærk drivlinje med 1000 rpm indsugningsgearkasse for reduceret belastning på traktorens PTO. Dobbeltløbende rullelejer på drivsiden af alle valser giver robust pålidelighed gennem mange tusinde baller

- .

- Fuldautomatisk drift med animeret realtidsdisplay, der holder føreren afslappet og fuldt produktiv gennem lange arbejdsdage

- .

Funktioner

Funktioner

How FastBale Premium Works

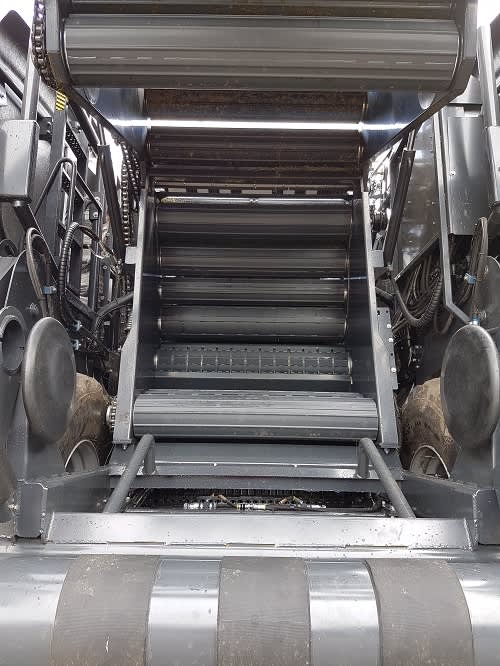

FastBale Premium features two bale chambers – a full sized main chamber and a pre-chamber which is about two thirds of the size of the main chamber.

Baling starts in the conventional manner with the main chamber producing the first bale. However, once the bale is fully formed, instead of having to stop to apply the net, FastBale Premium diverts the crop flow to the pre-chamber.

This allows the net to be applied to the bale in the main chamber and for the bale to be ejected onto the wrapper. When the pre-chamber is full, the incoming crop flow, together with the pre-compressed crop are both then transferred into the main bale chamber. Here the bale is formed to its final size and density.

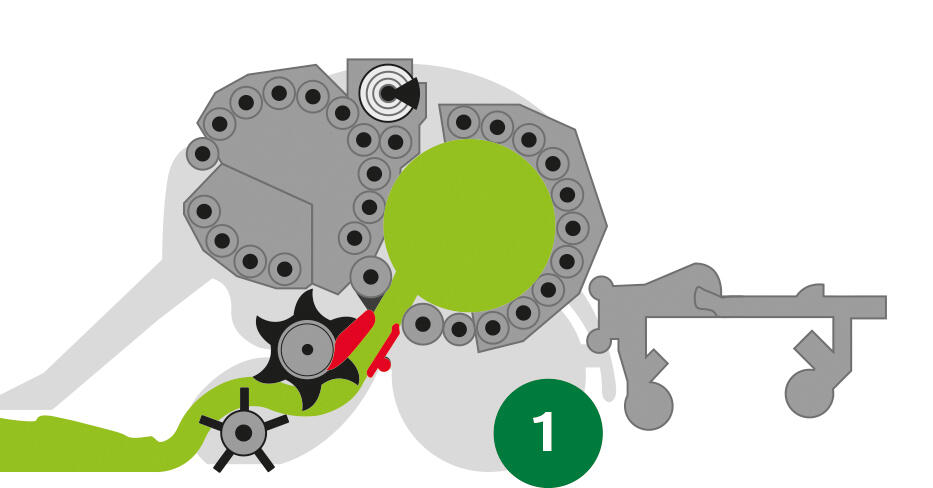

1.The bale is formed in the main bale chamber in the conventional manner until the required density is reached.

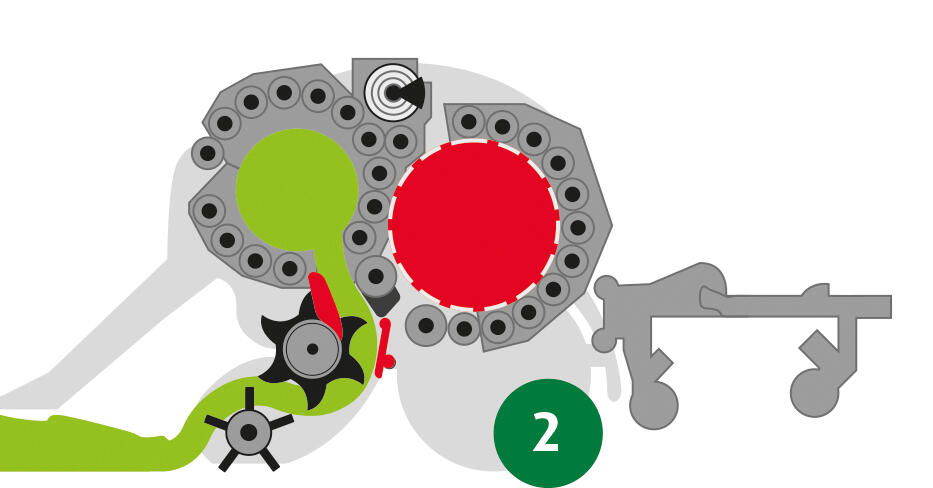

2. When the bale is fully formed, the crop flow, is diverted to pre-chamber, while net is applied to the completed bale.

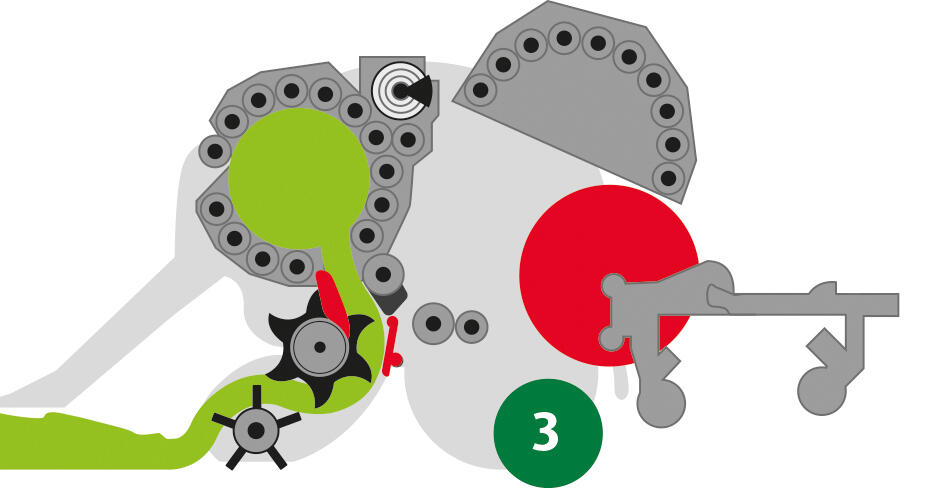

3. The tailgate opens and the completed bale rolls directly on to the wrapper by gravity.

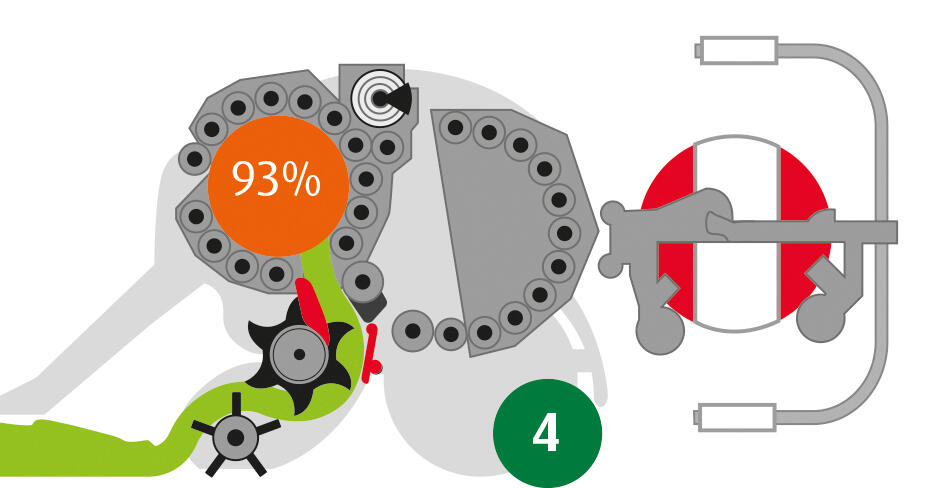

4. The wrapper is raised to its working position and wrapping commences.

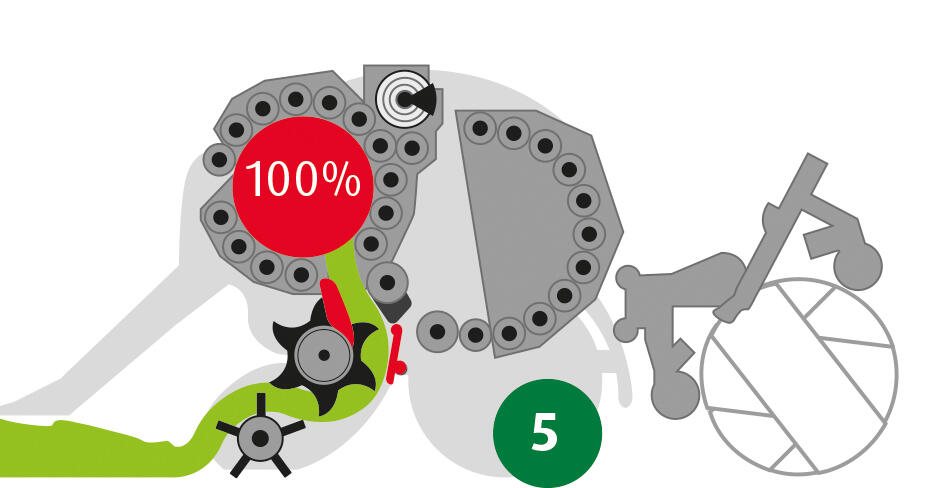

5.Crop flow continues to fill the pre-chamber until the pre-set density is reached.

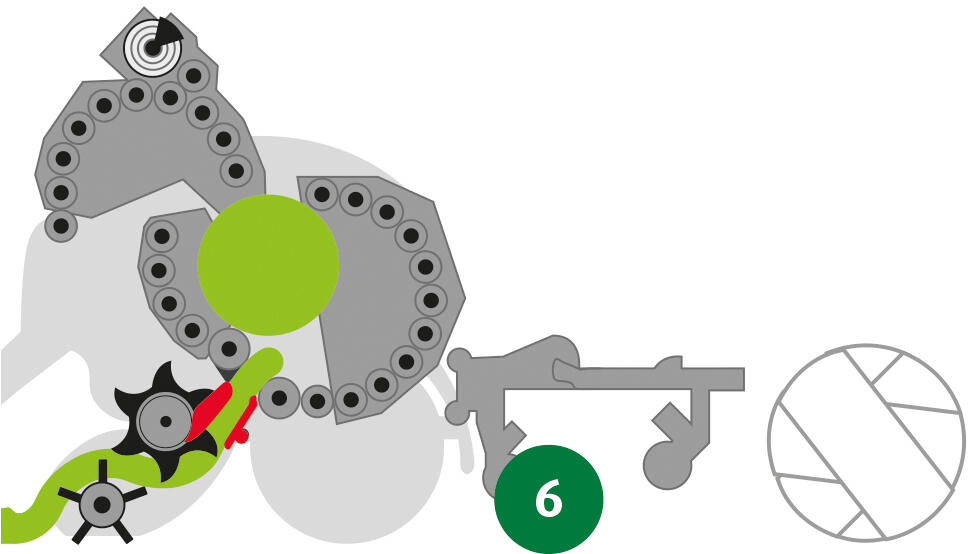

6. Crop flow and pre-compressed crop are transferred to the main bale chamber.

FastBale Premium has been built with maximum reliability in mind and incorporates many features to increase long term durability:

- Integrated main input gearbox with 1000 rpm input speed distributes drive to the various elements while keeping loading on the PTO shaft and tractor PTO clutch to a minimum.

- Separate drivelines power the intake rotor, pre-chamber and main bale chamber, with all bale chamber drives handled by heavy duty 1¼” pitch chains.

- All bale chamber rollers feature 50mm diameter bearings at both ends, with the drive side being equipped with double row roller bearings for maximum load capability.

- Long life for chamber roller and intake rotor bearings is assured by an automatic greasing system, while chain drives are provided with an automatic lubrication system.

Complex bale transfer systems have been completely eliminated. The wrapper is lowered to receive the bale directly from the main bale chamber.

The wrap-around main frame also avoids any risk of a bale being lost over the back of the wrapper when working on sloping land, improving operational safety compared to other systems.

FastBale Premium’s innovative wrapping system incorporates twin satellites which rotate about the vertical axis, with the bale supported on two powered rollers. This layout substantially reduces the space required for rotation of the film, resulting in a more compact machine, faster operation and higher precision in wrapping.

Film on Film

FastBale Premium is available with a film on film option. Some of the benefits of this technique include improved silage quality, easier handling and feeding out of bales and simpler recycling of plastic waste.

FastBale Premium non-stop technology brings added benefits when working with Film-on-Film.

Conventional baler-wrappers have to stop to apply net to the bale, which takes at least 5 seconds, plus more time to open/close the tailgate. Wrapping with net replacement film needs more wraps due to the ‘tail’ which has to be formed at beginning and end of cycle.

This results in the binding cycle taking over 10 seconds – so at least 5 seconds extra spent stationary for every bale made.

FastBale Premium continues baling during binding so all of this time is saved.

FastBale Premium has a unique method of discharging the wrapped bale. When wrapping is complete, the rear roller is lifted. This gently places the bale onto the ground, rather than rolling it off the wrapping table, greatly reducing the risk of the bale rolling away when working on sloping land.

Bale turner

The optional bale turner allows wrapped bales to be discharged on their end, where the increased number of film layers provides enhanced protection against damage from coarse crop stubbles or stones.

The innovative yet simple design utilises the lifting action of FastBale Premium’s wrapper frame to turn the bale while still on the move, maintaining the non-stop capability of FastBale Premium, with no requirement for any additional hydraulic functions.

This ingenious solution is very compact – during the bale wrapping process the bale turner is stowed under the front wrapper roller, with the result that FastBale Premium retains its class leading compact dimensions in both work and transport. A further plus point is that the bale turner does not need to be folded away manually prior to road transport. If the bale turner is not required, it can be left in place and simply locked in its parked position with the operating link disconnected, allowing bales to be discharged in the conventional manner.

FastBale Premium provides fully automatic operation. The result is that not only is productivity significantly increased, but stress and fatigue for the operator are reduced. The only operation the operator needs to choose is whether to control the release of the wrapped bale. Elimination of stop-start operation also gives a significant reduction in wear and tear on the tractor transmission.

FastBale Premium is equipped with a hydraulically operated net roll lifting device, providing easy loading. The net cradle lifts the roll to the correct position, it then simply slides into the net system.

The device also conveniently stores a spare roll of net.

Convenient film roll changeover

Simple film roll loading using the remote slow speed satellite rotate button. Both rolls can be changed while standing in the same position.

10 roll capacity

Two rolls of film in use, with on machine storage for a further eight rolls.

Great Things Come in Small Packages!

Despite its non-stop capability, FastBale Premium is extremely compact. With its pre-chamber located above the large diameter intake rotor and several chamber rollers shared between both bale chambers, mechanical complexity is kept to a minimum.

Combined with its revolutionary vertical folding satellite wrapping system, convenient road transport and easy access to even the tightest of fields is assured.

How FastBale Premium Works

FastBale Premium features two bale chambers – a full sized main chamber and a pre-chamber which is about two thirds of the size of the main chamber.

Baling starts in the conventional manner with the main chamber producing the first bale. However, once the bale is fully formed, instead of having to stop to apply the net, FastBale Premium diverts the crop flow to the pre-chamber.

This allows the net to be applied to the bale in the main chamber and for the bale to be ejected onto the wrapper. When the pre-chamber is full, the incoming crop flow, together with the pre-compressed crop are both then transferred into the main bale chamber. Here the bale is formed to its final size and density.

1.The bale is formed in the main bale chamber in the conventional manner until the required density is reached.

2. When the bale is fully formed, the crop flow, is diverted to pre-chamber, while net is applied to the completed bale.

3. The tailgate opens and the completed bale rolls directly on to the wrapper by gravity.

4. The wrapper is raised to its working position and wrapping commences.

5.Crop flow continues to fill the pre-chamber until the pre-set density is reached.

6. Crop flow and pre-compressed crop are transferred to the main bale chamber.

Complex bale transfer systems have been completely eliminated. The wrapper is lowered to receive the bale directly from the main bale chamber.

The wrap-around main frame also avoids any risk of a bale being lost over the back of the wrapper when working on sloping land, improving operational safety compared to other systems.

FastBale Premium’s innovative wrapping system incorporates twin satellites which rotate about the vertical axis, with the bale supported on two powered rollers. This layout substantially reduces the space required for rotation of the film, resulting in a more compact machine, faster operation and higher precision in wrapping.

Film on Film

FastBale Premium is available with a film on film option. Some of the benefits of this technique include improved silage quality, easier handling and feeding out of bales and simpler recycling of plastic waste.

FastBale Premium non-stop technology brings added benefits when working with Film-on-Film.

Conventional baler-wrappers have to stop to apply net to the bale, which takes at least 5 seconds, plus more time to open/close the tailgate. Wrapping with net replacement film needs more wraps due to the ‘tail’ which has to be formed at beginning and end of cycle.

This results in the binding cycle taking over 10 seconds – so at least 5 seconds extra spent stationary for every bale made.

FastBale Premium continues baling during binding so all of this time is saved.

FastBale Premium has a unique method of discharging the wrapped bale. When wrapping is complete, the rear roller is lifted. This gently places the bale onto the ground, rather than rolling it off the wrapping table, greatly reducing the risk of the bale rolling away when working on sloping land.

Bale turner

The optional bale turner allows wrapped bales to be discharged on their end, where the increased number of film layers provides enhanced protection against damage from coarse crop stubbles or stones.

The innovative yet simple design utilises the lifting action of FastBale Premium’s wrapper frame to turn the bale while still on the move, maintaining the non-stop capability of FastBale Premium, with no requirement for any additional hydraulic functions.

This ingenious solution is very compact – during the bale wrapping process the bale turner is stowed under the front wrapper roller, with the result that FastBale Premium retains its class leading compact dimensions in both work and transport. A further plus point is that the bale turner does not need to be folded away manually prior to road transport. If the bale turner is not required, it can be left in place and simply locked in its parked position with the operating link disconnected, allowing bales to be discharged in the conventional manner.

FastBale Premium has been built with maximum reliability in mind and incorporates many features to increase long term durability:

- Integrated main input gearbox with 1000 rpm input speed distributes drive to the various elements while keeping loading on the PTO shaft and tractor PTO clutch to a minimum.

- Separate drivelines power the intake rotor, pre-chamber and main bale chamber, with all bale chamber drives handled by heavy duty 1¼” pitch chains.

- All bale chamber rollers feature 50mm diameter bearings at both ends, with the drive side being equipped with double row roller bearings for maximum load capability.

- Long life for chamber roller and intake rotor bearings is assured by an automatic greasing system, while chain drives are provided with an automatic lubrication system.

Great Things Come in Small Packages!

Despite its non-stop capability, FastBale Premium is extremely compact. With its pre-chamber located above the large diameter intake rotor and several chamber rollers shared between both bale chambers, mechanical complexity is kept to a minimum.

Combined with its revolutionary vertical folding satellite wrapping system, convenient road transport and easy access to even the tightest of fields is assured.

FastBale Premium is equipped with a hydraulically operated net roll lifting device, providing easy loading. The net cradle lifts the roll to the correct position, it then simply slides into the net system.

The device also conveniently stores a spare roll of net.

Convenient film roll changeover

Simple film roll loading using the remote slow speed satellite rotate button. Both rolls can be changed while standing in the same position.

10 roll capacity

Two rolls of film in use, with on machine storage for a further eight rolls.

FastBale Premium provides fully automatic operation. The result is that not only is productivity significantly increased, but stress and fatigue for the operator are reduced. The only operation the operator needs to choose is whether to control the release of the wrapped bale. Elimination of stop-start operation also gives a significant reduction in wear and tear on the tractor transmission.

Præcisionslandbrug

Præcisionslandbrug

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

Teknisk specifikation

Teknisk specifikation

Download brochure| Kverneland FastBale | ||

|---|---|---|

| Bale chamber: | 17 main chamber,14pre-chamber (11+3 rollers shared) | |

| Bale size (m): | Ø1.25 -1.27 | |

| Intake: | SuperCut-25 | |

| Binding: | Net |

Teknisk specifikation

Teknisk specifikation

Download brochureBale diameter |

Intake System |

Binding |

|

FastBale |

1.26 x 1.27m |

800mm intake rotor with 25 knife chopping system |

Net or Film binding |

IsoMatch Tellus PRO

IsoMatch Tellus PRO

IsoMatch Tellus GO+

IsoMatch Tellus GO+

IsoMatch MultiEye

IsoMatch MultiEye