Kverneland 53100

Racebil-teknologi til slåmaskiner

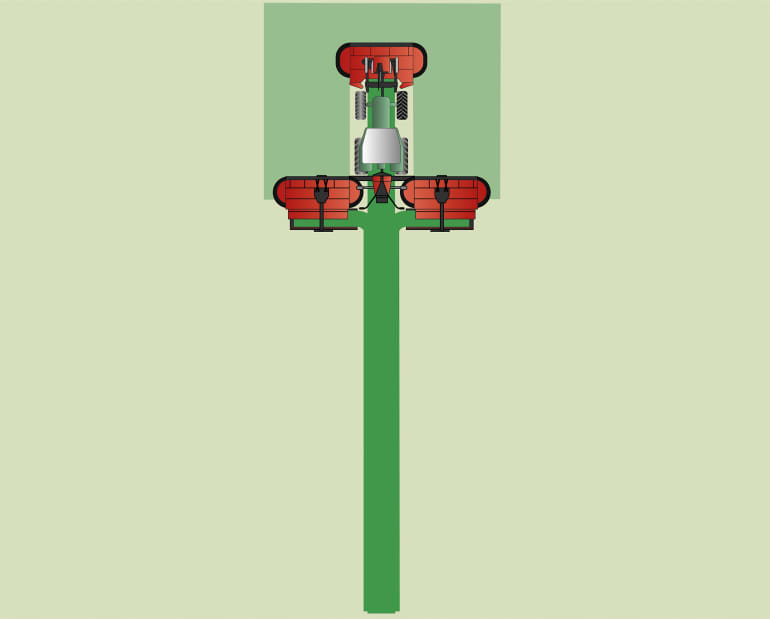

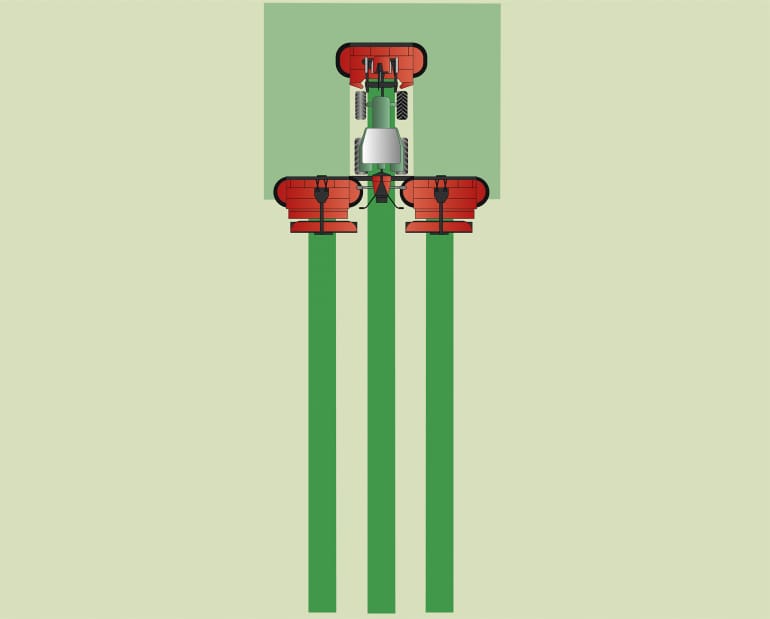

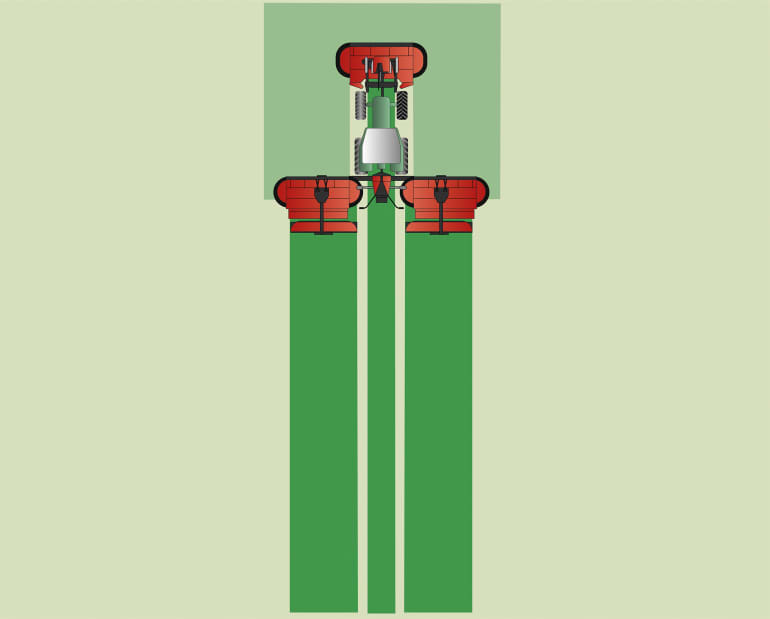

Tredobbelt slåmaskinekombination med QuattroLink-affjedring, SemiSwing- eller valsekonditioner, hydraulisk justering af arbejdsbredde og overlapning og valgfrit BX-båndudstyr.

Højdepunkter

Innovativt QuattroLink racerbilsophængskoncept ISOBUS - intuitiv joystick- eller terminalstyring Fleksibel affjedring - 700 mm lodret bevægelse NonStop BreakBack-beskyttelse i fuld bredde Hydraulisk justering af overlap undervejsBeskrivelse

Kverneland 53100 Vario-serien er fuldt ISOBUS-kompatibel og leverer en enestående ydelse med sit affjedringskoncept, 10,20 m arbejdsbredde og hydraulisk on-the-go-justering af arbejdsbredde og overlapning samt BX-båndudstyr som ekstraudstyr. Kverneland 53100 Vario-serien er udstyret med QuattroLink-affjedring. Fire ophængsarme monteret på en fast bærearm, der gør det muligt for klippeaggregatet at svæve uafhængigt over marken og trække klippeaggregatet. BX-båndudstyret (ekstraudstyr) tilpasser automatisk båndhastigheden til arbejdsbredden, så du får den samme ensartede skårbredde, uanset hvor klippeaggregaterne er placeret.

Højdepunkter

- ISOBUS-styring

- ISOBUS-styring med intuitivt joystick eller terminalstyring.

- Automatisk justering af båndhastighed

- Justerbar båndhøjde

- Bælteforstærkning til foragerdrift

- Autostop-funktion til minimalt brændstofforbrug.

- Mangfoldig 4-i-1-løsning

- Fleksibelt ophæng - 700 mm bevægelser, 400 mm opad og 300 mm nedad.

- NonStop BreakBack-beskyttelse i hele arbejdsbredden.

- Hydraulisk justering af overlap under kørsel.

- Minimum 500 mm frihøjde ved vendinger på forageren.

- Integrerede parkeringsfødder til lodret opbevaring.

Funktioner

Same Uniform Swath Formation...

Kverneland BX automatically adjusts belt speed, whenever a change is needed. If mowing units are sideshifted to adjust overlap, belt speed immediately adjusts, to compensate for the change in throwing distance needed. When increasing overlap for mowing around corners, belt speed is lowered.

...Even When Using Just One Belt

In addition Kverneland BX also detects when a belt or mowing unit is raised, and immediately compensates to ensure crop stays within the intended swath width. Belt speed of the working belt is automatically reduced, to avoid crop “flying over” the centre swath.

Shape the Swath As You Want

Working in heavy first cut crop, combined with a narrow pick-up width of the following machine, may cause challenges in getting the swath narrow enough. Kverneland BX offers the possibility of positioning the swath belt in different operating heights, to deliver the crop on top of the swath made by the front mower, to make a narrow and box shaped swath. Delivery height is set by lowering or raising the belt hydraulically on-the-go.

Clean and Tidy Headlands

When the mowing units are activated for headland lift, an integrated belt boost automatically speeds up, to empty the belts before they are raised, leaving a clean and tidy headland. Furthermore the AutoStop is activated once belts are raised, automatically stopping them until mowing units are lowered again, keeping fuel consumption low.

4-In-1 Solution

Versatility via four-in-one solution offered by the Kverneland 53100 BX, allowing one large swath, three single swaths, full width wide spreading, or using one belt only. The standard fitted swath plates are easily slided into position for the desired swath width. If conditions require wide spreading, the standard fitted FlipOver wide spreading vanes are activated in seconds.

Racecar Technology Applied for Mower Conditioners

What makes the QuattroLink suspension unique? The mowing unit is pulled by four suspension arms fitted onto a fixed carrying arm that allows the mowing unit to float independently over the field, adjusting highly accurately and instantly to any changes in ground contours.

No Compromises on Flexibility

The mowing pattern is extremely flexible with a vertical working range of 700mm up and down and a transverse working range of 30°. The 4 arm suspension concept ensures constant ground pressure during working operations.

How You Will Benefit from QuattroLink

Like a race car you want better tracking, ability to go at faster speed and adjust instantly to changing field conditions when operating your mower conditioner. These are the main benefits you will experience when running the kverneland 3300 series and 53100 MT Vario. The four suspension arms provide the mowing unit with an exceptional flexibility in adapting instantly to demanding ground contours inviting for higher speed and more productivity.

Hydraulic Adjustment of Overlap

Kverneland 3336 MT Vario and 53100 MT Vario are fitted with hydraulic SideShift integrated into the carrying arm allowing each mowing units to move 400mm. To easily compensate for changing field conditions, the adjustable overlap is designed as a telescopic arm, directly into the suspension.

Ground Pressure Remains Constant

During mowing operation the carrying arm always remains even to the ground, giving the mowing unit the freedom to instantly compensate and float across uneven ground contours. The true benefit of the suspension concept is that even though overlap is changed, the chosen ground pressure remains the same.

GEOMOW unlocks the full potential of the Kverneland 53100 MT Vario. The all-new Kverneland GEOMOW application delivers automatic headland lift via section control.

GEOMOW removes the risk of mistakes when lifting mowing units too early, or lowering them too late. When reaching the end of the field, the front mower is automatically raised as it hits already cut grass on headlands, rear units are lifted at the right time as well, allowing the operator to fully focus on turning as efficiently as possible.

Our NonStop BreakBack system just got even better. With the new QuattroLink suspension this system now offers protection across the full working width of the mower, including the part closest to the tractor. There are no limiting factors on the inside part of the mower, giving the driver true peace of mind. When hitting an obstacle in the field, the mowing unit will instantly move backwards and up, and then return to the original position.

With the optional Kverneland quick-coupler solution, it is now possible to dismount the two BX belts in less than 10 minutes and park them safely on specially designed transport rollers. When disconnected, the BX belts automatically disappear from the terminal screen.

This gives you the option of deciding from day to day, when work schedule is ready, if belts are needed or not. All it takes are three simple steps – no tools required!

1. Slide the purpose-built transport rollers onto the BX-belt and remove the connection pin.

2. Disconnect the power cable and all hydraulic connections to BX belt with one single lever.

3. Lower the mowing units and the BX belt automatically comes off.

Præcisionslandbrug

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

Teknisk specifikation

Teknisk specifikation

Download brochure| Model | 53100 MT Vario | 53100 MT Vario BX | 53100 MR Vario | 53100 MR Vario BX | |

|---|---|---|---|---|---|

| Type crimper | SemiSwing | SemiSwing | Valse | Valse | |

| Arbejdsbredde m(ft) | 9.80/10.20 (32'2"/33'5") | 9.80/10.20 (32'2"/33'5") | 9.80/10.20 (32'2"/33'5") | 9.80/10.20 (32'2"/33'5") | |

| Transportbredde m(ft) | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | 2.90(9'6") | |

| PTO (rpm) | 1000 | 1000 | 1000 | 1000 | |

| Krævet PTO-effekt min (kW/hk) | 150/200 | 175/240 | 150/200 | 175/240 | |

| Antal skiver/knive | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 | 2x9/2x18 |

Teknisk specifikation

Teknisk specifikation

Download brochure

|

Working Width |

Number of Discs |

Conditioner |

53100 MT Vario BX |

9.80-10.20m |

2 x 9 discs |

SemiSwing Steel Tine Conditioner |

53100 MR Vario BX |

9.80-10.20m |

2 x 9 discs |

Roller Conditioner |

IsoMatch Tellus GO+

IsoMatch Tellus GO+