Kverneland Exacta CL GEOSPREAD

GPS-styret, intelligent spredning.

CL GEOSPREAD vejningsspreder til det mellemstore markedssegment.

Højdepunkter

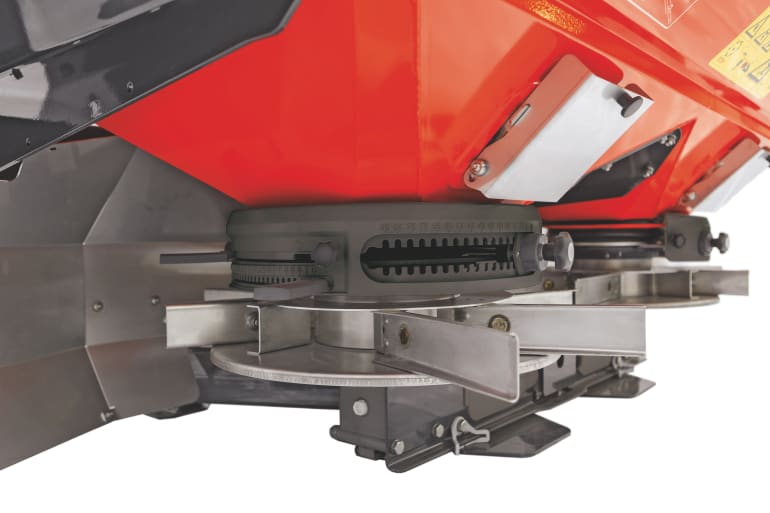

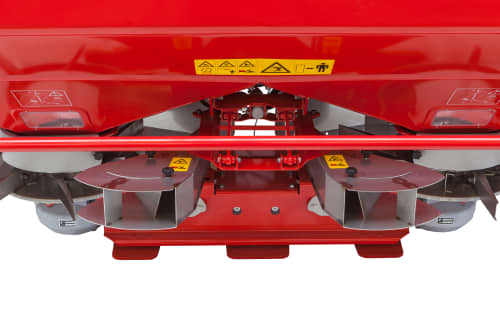

- CentreFlow-spredningssystem

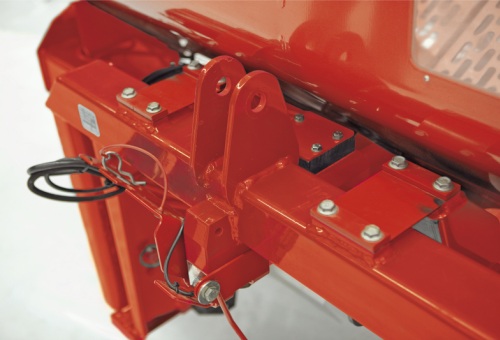

- Vejningssystem med unik referencesensor

- Forebyg overlapning med GEOSPREAD-systemet

- MULTIRATE: flere hastigheder inden for en arbejdsbredde

- Sektionskontrol med 1 meter sektioner

Beskrivelse

Kverneland Exacta CL GEOSPREAD er den ideelle spreder til agerbrugslandmænd og professionelle mælkeproducenter. GEOSPREAD-systemet foretager sektionsstyring med sektioner på kun 1 meter. Med et maksimum på 33 sektioner og muligheden for at skifte sektioner over midten er unødvendig overlapning sat til et absolut minimum. De 4 vejeceller og referencesensoren er vigtige funktioner, da nøjagtig vejning er afgørende for sektionskontrol. Den samlede fordel ved GEOSPREAD kombineret med hastighedsrelateret spredning og GEOPOINT-styring af foragre kan være op til 15 %. Dette kan opnås ved at spare gødning og bedre udbytte på grund af unødvendig overlapning. I kombination med MULTIRATE, den variable tildeling, som anvender flere tildelinger inden for en arbejdsbredde, kan der opnås en endnu mere omkostningseffektiv spredning. Denne Kverneland Exacta CL GEOSPREAD spreder er ISOBUS-kompatibel og AEF-certificeret. Du kan betjene sprederen i kombination med IsoMatch Tellus PRO, IsoMatch Tellus GO+ eller enhver anden ISOBUS-kompatibel traktorterminal.

Højdepunkter

- CentreFlow-spredesystem

- Fuldt automatisk vejesystem med unik referencesensor

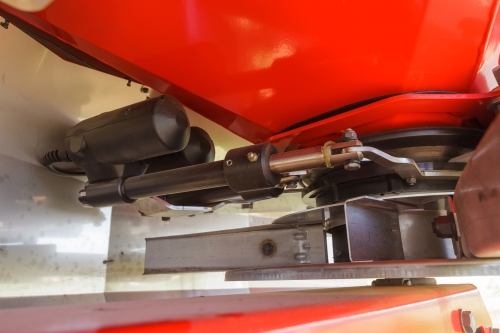

- Unikt GEOSPREAD-system med to elektriske aktuatorer

- Sektionsstyring med sektioner på 1 meter op til maksimalt 33 (afhængigt af terminalens funktionalitet)

- ISOBUS 11783-kompatibel for nem plug and play

- Muligt i kombination med IsoMatch GEOCONTROL

- MULTIRATE for at anvende flere satser inden for en arbejdsbredde

Funktioner

Funktioner

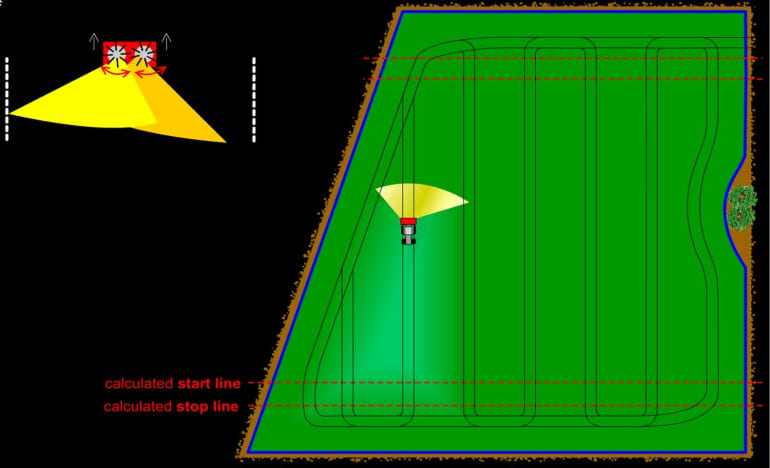

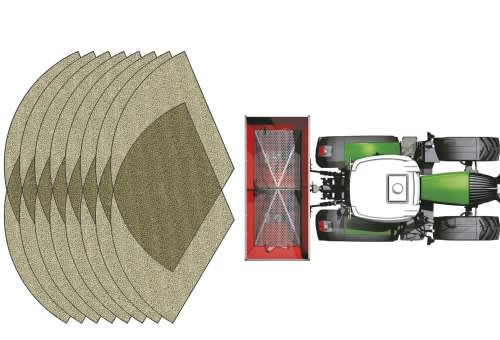

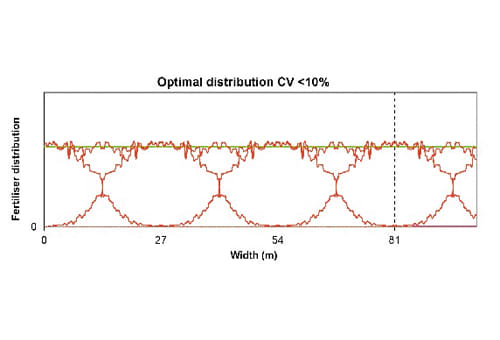

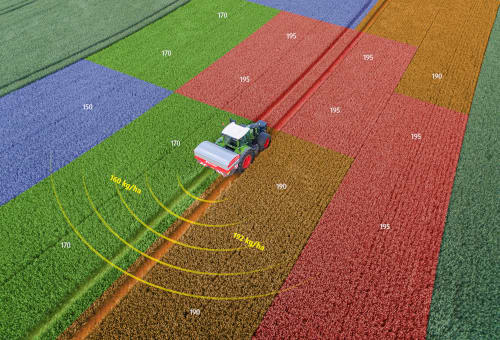

When running IsoMatch GEOCONTROL in addition to GEOSPREAD you can set the Exacta CL, TL and TLX GEOSPREAD more accurately. The working width will be automatically adjusted to suit the overlap and coverage using a GPS positioning system. For example, when driving in a wedge or irregular shaped field, GEOSPREAD will start to decrease the working width step by step. GEOSPREAD is using the section control function of the IsoMatch GEOCONTROL software which is in the IsoMatch Tellus PRO or IsoMatch Tellus GO terminal. The spreader working width is divided into a minimum of 1 metre sections (max. 45 sections on TLX GEOSPREAD, max. 54 sections on TL GEOSPREAD and max. 33 sections on CL GEOSPREAD. Not only the spreading width is adjusted, the application rate (kg/min) is also adjusted automatically to match the revised spreading width. This unique combination of working width and application rate adjustment makes the GEOSPREAD system extremely accurate, with minimum influence on the spread pattern coefficient of variation.

The Advantages:

- Quick and accurate spreading, due to the actuators being directly connected to the discharge point. No linkages.

- Stable disc RPM in combination with discharge point adjustment maintains the spreading pattern (coefficient of variation)

- Section control with 1 metre sections (depending on the terminal functionality)

- Easy operation; no need to step off the tractor to adjust the working width

- 100% ISOBUS compatible for easy operation

- Automatic start/stop with GPS on headlands possible

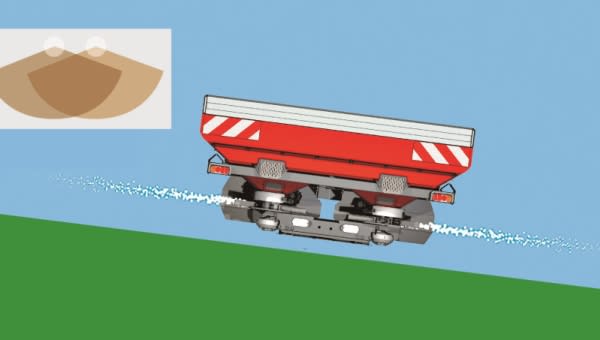

- No impact, no fragmentation, no dust: Central release point, smooth acceleration and centrifugal force accelerates fertiliser up to disc speed before it reaches the vane.

- Accurate spreading pattern: A double overlap spreading pattern gives unrivalled accuracy. The 8 vanes per discs are ensuring a continous flow of fertiliser to the field. This is important for high capacity spreading and forward speed.

- Minimal wind influence, maximum tolerance: Flat discs and a horizontal flow of fertiliser give a symmetrical spreading pattern.

- Consistent spreading pattern: Eight vanes per disc, eight sectors per revolution give an equal distribution. Double overlap spreading pattern.

- Guaranteed accuracy on slopes: guaranteed accuracy on slopes. The fertiliser always contacts the vanes at the same point, also on slopes and travels the complete length of the vane.

- Continuous dynamic "online - calibration" with high frequency communication signal.

- Kvernelands unique reference sensor technology: all negative influences are automatically corrected and eliminated, ensuring utmost spreading accuracy even on hill sides. The Kverneland reference sensor gives you absolute accuracy, because every kilo counts!

- Load cells in combination with the unique reference sensor:

- Auto calibrating and continuous weighing system

- Automatic correction on slopes

- Automatic correction of shocks, even on rough terrain

- Automatic speed related dosing system

- No calibration test needed

- Highest accuracy in all conditions: even spreading quality guaranteed! Save costs and increase quality!

- The compact EasySet 'dashboard' gives you considerably simplified accurate setting and adjustment of application rates. Two hydraulically operated metering plates, each with three discharge openings ensure an equal fertiliser flow from the hopper to the spreading discs.

- The development department of Kvernelands spreader R&D team has its own spreader competence centre in order to allow continuous testing throughout the year. All test are carried out according to the strictest international standards and quality requirements.

- The key to accurate spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible. The Kverneland Exacta checklist helps you to ensure consistent accuracy in all field conditions

1. Select fertiliser type

2. Determine granule size and distribution

3. Determine litre weight

- Direct access to the most recent test results at: www.kvernelandspreadingcharts.com or download the spreading charts Application via the App Store or get it on Google Play

- Kverneland offers the ExactLine system or manual/hydraulic border spreading plate for border spreading. The ExactLine can be accurately set for all types of fertiliser and for all working widths. Operation is easy, no need to leave the tractor seat. For the HL, TL and TLX models the ExactLine can even be fitted on the left and right hand side of the spreader.

- With one-side boundary spreading the tractor is driven approximately 2 metres from the field border.

- With boundary track spreading the tractor is driving in the first tramline and is spreading to the border. The distance to the border is the half of the working width.

- The Border Spreading Indicator (BSI), indicates which border spreading device is active.

For easy and cost effective spreading

MULTIRATE (Variable Rate Application) applies multiple rates within a working width.

In order to spread the right amount of fertiliser at a specific place in a field there is a need to have a different rate within the working width. Depending on the field variation and the size of the grid of the variable application map, input of 2, 4, 6 or 8 rate sections can be used. This means a more accurate application of nutrients to have a better nutrient efficiency, better yield and reduce costs.

With a Kverneland GEOSPREAD spreader you invest in 100% ISOBUS compatibility for easy plug and play with the IsoMatch Tellus PRO or any other AEF certified terminal. In just some steps with this combination you are ready to use MULTIRATE. You have to convert a satellite or soil map into an ISO-XML file. Download the Variable Rate Map into the terminal and you are ready to spread with MULTIRATE with 2 up to 8 rates.

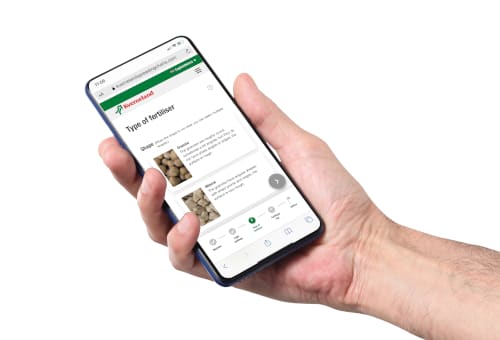

With the AutosetApp you have always the most up to date settings for your weighing spreader available. The AutosetApp is an App (software application) available on the IsoMatch Tellus PRO or IsoMatch Tellus GO+ terminal. The AutosetApp is standard integrated into the IsoMatch GEOCONTROL software. This App connects the terminal directly with the GEOSPREAD weighing spreader and will automatically adjust the spreader according to the settings entered into the App. The AutosetApp will also work in combination with the CL-EW, W PRO and TL, with the exception being for those spreaders the discharge point (letter setting) still needs to be adjusted manually on the spreader itself. |

The Kverneland fertiliser spreader database with the most up to date spreading charts is always available online. The AutosetApp can connect to the fertiliser spreading database in two different ways. You can connect it to the online database via the IsoMatch Wireless WIFI USB adapter or download the most actual database from the website www.kvernelandspreadingcharts.com on an USB stick and upload the database directly into the IsoMatch Tellus or IsoMatch Tellus GO+ terminal.

- Easy to assemble aluminium hopper extensions are available to increase hopper capacity.

- An easy to fold in and out hopper cover is as option availble. Simple to fit!

- Left/right shut off valve for spreading at half working widths is optional available.

- To ensure a consistent flow when spreading low quantities, the CentreFlow system is equipped with a fine application kit. Ideal for spreading low quantities, seeds and slug pellets.

- Delta shaped heavy duty grids are standard equipment of the Exacta CL spreader.

- A hopper emptying kit is available for easy emptying of the last fertiliser granules out of the hopper.

- A tramline cylinder, manual or hydraulic border spreading plate or ExactLine border spreading device can be ordered for easy border spreading.

- Long life LED lights are optional available.

- The compact EasySet 'dashboard' gives you considerably simplified accurate setting and adjustment of applicaton rates. Two hydraulically operated metering plates, each with three discharge openings ensure an equal fertiliser flow from the hopper to the spreading discs.

- The development department of Kvernelands spreader R&D team has its own spreader competence centre in order to allow continuous testing throughout the year. All test are carried out according to the strictest international standards and quality requirements.

- The key to accurate spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible. The Kverneland Exacta checklist helps you to ensure consistent accuracy in all field conditions

1. Select fertiliser type

2. Determine granule size and distribution

3. Determine litre weight

- Direct access to the most recent test results at: www.kvernelandspreadingcharts.com or download the spreading charts Application via the App Store or get it on Google Play

- Easy to assemble aluminium hopper extensions are available to increase hopper capacity.

- An easy to fold in and out hopper cover is as option availble. Simple to fit!

- Left/right shut off valve for spreading at half working widths is optional available.

- To ensure a consistent flow when spreading low quantities, the CentreFlow system is equipped with a fine application kit. Ideal for spreading low quantities, seeds and slug pellets.

- Delta shaped heavy duty grids are standard equipment of the Exacta CL spreader.

- A hopper emptying kit is available for easy emptying of the last fertiliser granules out of the hopper.

- A tramline cylinder, manual or hydraulic border spreading plate or ExactLine border spreading device can be ordered for easy border spreading.

- Long life LED lights are optional available.

When running IsoMatch GEOCONTROL in addition to GEOSPREAD you can set the Exacta CL, TL and TLX GEOSPREAD more accurately. The working width will be automatically adjusted to suit the overlap and coverage using a GPS positioning system. For example, when driving in a wedge or irregular shaped field, GEOSPREAD will start to decrease the working width step by step. GEOSPREAD is using the section control function of the IsoMatch GEOCONTROL software which is in the IsoMatch Tellus PRO or IsoMatch Tellus GO terminal. The spreader working width is divided into a minimum of 1 metre sections (max. 45 sections on TLX GEOSPREAD, max. 54 sections on TL GEOSPREAD and max. 33 sections on CL GEOSPREAD. Not only the spreading width is adjusted, the application rate (kg/min) is also adjusted automatically to match the revised spreading width. This unique combination of working width and application rate adjustment makes the GEOSPREAD system extremely accurate, with minimum influence on the spread pattern coefficient of variation.

The Advantages:

- Quick and accurate spreading, due to the actuators being directly connected to the discharge point. No linkages.

- Stable disc RPM in combination with discharge point adjustment maintains the spreading pattern (coefficient of variation)

- Section control with 1 metre sections (depending on the terminal functionality)

- Easy operation; no need to step off the tractor to adjust the working width

- 100% ISOBUS compatible for easy operation

- Automatic start/stop with GPS on headlands possible

- No impact, no fragmentation, no dust: Central release point, smooth acceleration and centrifugal force accelerates fertiliser up to disc speed before it reaches the vane.

- Accurate spreading pattern: A double overlap spreading pattern gives unrivalled accuracy. The 8 vanes per discs are ensuring a continous flow of fertiliser to the field. This is important for high capacity spreading and forward speed.

- Minimal wind influence, maximum tolerance: Flat discs and a horizontal flow of fertiliser give a symmetrical spreading pattern.

- Consistent spreading pattern: Eight vanes per disc, eight sectors per revolution give an equal distribution. Double overlap spreading pattern.

- Guaranteed accuracy on slopes: guaranteed accuracy on slopes. The fertiliser always contacts the vanes at the same point, also on slopes and travels the complete length of the vane.

- Continuous dynamic "online - calibration" with high frequency communication signal.

- Kvernelands unique reference sensor technology: all negative influences are automatically corrected and eliminated, ensuring utmost spreading accuracy even on hill sides. The Kverneland reference sensor gives you absolute accuracy, because every kilo counts!

- Load cells in combination with the unique reference sensor:

- Auto calibrating and continuous weighing system

- Automatic correction on slopes

- Automatic correction of shocks, even on rough terrain

- Automatic speed related dosing system

- No calibration test needed

- Highest accuracy in all conditions: even spreading quality guaranteed! Save costs and increase quality!

- The compact EasySet 'dashboard' gives you considerably simplified accurate setting and adjustment of applicaton rates. Two hydraulically operated metering plates, each with three discharge openings ensure an equal fertiliser flow from the hopper to the spreading discs.

- The development department of Kvernelands spreader R&D team has its own spreader competence centre in order to allow continuous testing throughout the year. All test are carried out according to the strictest international standards and quality requirements.

- The key to accurate spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible. The Kverneland Exacta checklist helps you to ensure consistent accuracy in all field conditions

1. Select fertiliser type

2. Determine granule size and distribution

3. Determine litre weight

- Direct access to the most recent test results at: www.kvernelandspreadingcharts.com or download the spreading charts Application via the App Store or get it on Google Play

- Kverneland offers the ExactLine system or manual/hydraulic border spreading plate for border spreading. The ExactLine can be accurately set for all types of fertiliser and for all working widths. Operation is easy, no need to leave the tractor seat. For the HL, TL and TLX models the ExactLine can even be fitted on the left and right hand side of the spreader.

- With one-side boundary spreading the tractor is driven approximately 2 metres from the field border.

- With boundary track spreading the tractor is driving in the first tramline and is spreading to the border. The distance to the border is the half of the working width.

- The Border Spreading Indicator (BSI), indicates which border spreading device is active.

With the AutosetApp you have always the most up to date settings for your weighing spreader available. The AutosetApp is an App (software application) available on the IsoMatch Tellus PRO or IsoMatch Tellus GO+ terminal. The AutosetApp is standard integrated into the IsoMatch GEOCONTROL software. This App connects the terminal directly with the GEOSPREAD weighing spreader and will automatically adjust the spreader according to the settings entered into the App. The AutosetApp will also work in combination with the CL-EW, W PRO and TL, with the exception being for those spreaders the discharge point (letter setting) still needs to be adjusted manually on the spreader itself. |

The Kverneland fertiliser spreader database with the most up to date spreading charts is always available online. The AutosetApp can connect to the fertiliser spreading database in two different ways. You can connect it to the online database via the IsoMatch Wireless WIFI USB adapter or download the most actual database from the website www.kvernelandspreadingcharts.com on an USB stick and upload the database directly into the IsoMatch Tellus or IsoMatch Tellus GO+ terminal.

- Easy to assemble aluminium hopper extensions are available to increase hopper capacity.

- An easy to fold in and out hopper cover is as option availble. Simple to fit!

- Left/right shut off valve for spreading at half working widths is optional available.

- To ensure a consistent flow when spreading low quantities, the CentreFlow system is equipped with a fine application kit. Ideal for spreading low quantities, seeds and slug pellets.

- Delta shaped heavy duty grids are standard equipment of the Exacta CL spreader.

- A hopper emptying kit is available for easy emptying of the last fertiliser granules out of the hopper.

- A tramline cylinder, manual or hydraulic border spreading plate or ExactLine border spreading device can be ordered for easy border spreading.

- Long life LED lights are optional available.

Præcisionslandbrug

Præcisionslandbrug

Lavet til smart, effektivt og nemt landbrug

IsoMatch GEOCONTROL er et avanceret software-program inden for IsoMatch Tellus og IsoMatch Tellus GO+, der hjælper dig med at styre alle ISOBUS kompatible Kverneland Group maskiner såsom sprøjter, spredere og såmaskiner! Kombineret med en GPS-modtager opfylder den fremtidens behov med hensyn til nemt, smart og effektivt landbrug!

Whether you are a farmer or contractor with a fleet, IsoMatch FarmCentre gives you a complete overview of your business. You can track the movement of your fleet in real time or verify later where your machines have been operating. Keeping track of multiple machines spread over vast areas has never been so easy! Additionally, all alerts and notifications are sent directly to the IsoMatch FarmCentre web application, and the history of alerts is saved. Allowing dealer to access your account for remote support will decrease the risk of downtime and increase your productivity. With IsoMatch FarmCentre, machine performance parameters can be tracked and analysed for optimal performance. Actual information about quantity of pressed bales, fertiliser consumption and more is shown in the application. All this you can check remotely from a computer or even a tablet or smartphone.

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 2 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

Connect to a local wireless network on your IsoMatch Tellus.

IsoMatch Wireless (USB-stick) is complementary to the IsoMatch Tellus and makes it easy to connect to a local wireless network, such as your phone’s hot-spot, home network etc.

No additional costs of an internet service provider. When connected via the IsoMatch Wireless you can browse the internet, view the weather, Gmail, Google, etc.

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus and IsoMatch Tellus GO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

Teknisk specifikation

Teknisk specifikation

Download brochure| Exacta CL GEOSPREAD (1100l) | Exacta CL GEOSPREAD (1300l) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Kapacitet af beholder (l) | 1100 | 1550 | 2000 | 2450 | 1300 | 1800 | 2300 | 2800 | |

| Påfyldningshøjde (cm) | 108 | 127 | 146 | 165 | 113 | 132 | 151 | 170 | |

| Bredde (cm) | 220 | 220 | 220 | 220 | 245 | 245 | 245 | 245 | |

| Fyldbredde (cm) | 214 | 214 | 214 | 214 | 239 | 239 | 239 | 239 | |

| Tomme vægt (kg) | 480 | 505 | 530 | 555 | 495 | 520 | 545 | 570 | |

| Spredningsbredde (m) | 10-24 (27-33)* | 10-24 (27-33)* | 10-24 (27-33)* | 10-24 (27-33)* | 10-24 (27-33)* | 10-24 (27-33)* | 10-24 (27-33)* | 10-24 (27-33)* | |

| Udbytte (kg/min) | 10-320 | 10-320 | 10-320 | 10-320 | 10-320 | 10-320 | 10-320 | 10-320 | |

| Kontrolelementer | ISOBUS | ISOBUS | ISOBUS | ISOBUS | ISOBUS | ISOBUS | ISOBUS | ISOBUS | |

| LED-belysningssæt | Tilvalg | Tilvalg | Valgmulighed | Valgmulighed | Tilvalg | Tilvalg | Valgmulighed | Valgmulighed | |

| Kantspredningsplade | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | |

| ExactLine-grænseudbredelsessystem | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed | Valgmulighed |

IsoMatch Tellus GO+

IsoMatch Tellus GO+

IsoMatch InLine

IsoMatch InLine

IsoMatch Global 2

IsoMatch Global 2