Kverneland 3224 MN - 3228 MN - 3232 MN

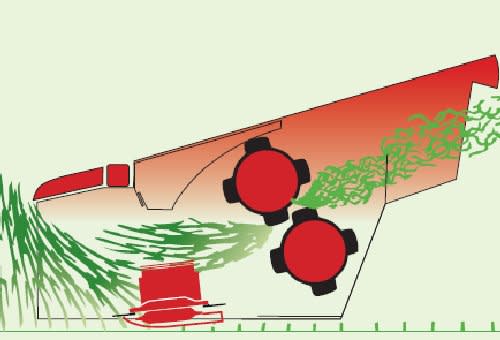

Centermonteret skårlægger med crimper og 125° vertikal transport position.

Højdepunkter

Centermonteret fjederophæng Valgfri hydraulisk fjederjustering Lodret transportløsning 600/900 rpm konditioneringsrotor Kverneland NonStop BreakBack-systemBeskrivelse

Kverneland har med 3200 MN serien introduceret tre nye modeller på det danske marked, med arbejdsbredder på 2,40 og 2,80 og 3,20 meter. Alle tre modeller er er udstyret med nylonfinger crimper, der gør maskinen lettere uden at gå på kompromi med crimper effekten.

Fordele

- Center monteret fjederophæng

- 2,40, 2,80 og 3,20 m arbejdsbredde

- Nylon fingercrimper

- Vertikal transportposition

- 600/900 Rpm crimperhastighed

- Kverneland BreakBack system

·

Funktioner

This feature provides easy and simple setting of the ground pressure. For greater operator comfort, ground pressure of the large suspension spring is set hydraulically from the tractor cab. On the hydraulic version the tension on the large suspension spring, which controls the ground pressure, is adjusted hydraulically, to increase or lower pressure. The chosen ground pressure level is conveniently registered from the easy-to-read scale

- The mower is folded into a 125° vertical transport position using a hydraulic cylinder.

- The low gravity point during transport, with the weight of the mower close to the tractor, provides an excellent weight distribution.

- The tractor and mower remains well balanced, even during high speed road transport, and the machine is fixed during transport by the hydraulic lifting arm.

- In addition transport height is limited, so passing through narrow gateways or under bridges is not a problem.

- Another benefit is that the hydraulic cylinder also supports quick lifting of the mower from working to headland position.

- The centre pivot suspension provides an even weight distribution of the 2500 H, 2836 M, 3224 MT, 3228 MT and 3132 MT and a uniform ground pressure over the complete working width, ensuring good ground contour following.

- The mowing units are suspended in the centre of gravity. This design provides a constant, faster and more precise adaptation to ground contours.

- The benefit is less skid wear, optimum protection of the stubble and less fuel consupmtion.

- The machines also offer a large degree of operating adaptability, as they are factory fitted with the option of being operated with either 540 or 1000 rpm.

- It requires no additional accessory. All that is needed is simply to turn the main gearbox on the suspension 180°.

- To offer maximum protection of the cutterbar, these machines are fitted with the well-known Kverneland BreakBack solution.

- When encountering an obstacle, the BreakBack will swing the machine backwards and over the obstacle, returning it to the original working position once the obstacle has been passed

- Due to the nylon tines fitted to the conditioner, the total weight of the machine is kept to a minimum, while keeping an aggressive conditioning.

- The fixed conditioning fingers are made from high quality nylon, to make them very rigid.

- This means excellent protection from stones and other obstacles. A perfect solution for farmer and smaller contractor machines!

- Kverneland uses round discs. Round discs are less susceptible to stone impact, and reduce shock loads in the transmission.

- Stones are expelled immediately, before they have any chance of becoming jammed. The benefits are lower repair and maintenance costs - at the same time as a clean and aggressive cut.

- The cutterbar has a high oil capacity, ensuring a very low working temperature. This ensures an efficient oil cooling and lubrication of the entire cutterbar.

- The long curved gear wheels running in oil provides a very quiet and reliable power transmission.

- The fully welded cutterbar gives a very stiff and strong design for high durability.

- With the ProFit quick knife change system, maintenance of the cutting ability is easy. The knives are changed by one simple operation using the special lever.

- The Kverneland roller versions are equipped with full width chevron rollers, quickly taking the cut crop off of the cutting discs and providing gentle and effective conditioning of fragile crops like lucerne/alfalfa, reducing leaf loss to a minimum.

- The design of the rollers ensures, that the crop is placed in an even, fluffy swath.

- The conditioning intensity is varied without use of tools, by adjusting the roller pressure exerted between top and bottom roller.

Som ekstraudstyr fås en stander til opbevaring i transportstilling, så maskinen fylder mindst muligt under vinteropbevaring

Teknisk specifikation

Teknisk specifikation

Download brochureArbejdsbredde |

Antal skiver |

Crimper |

Kraftbehov |

|

3224 MN |

2,40 m |

6 |

Nylonfingre |

50/70 kW/hk |

3228 MN |

2,80 m |

7 |

Nylonfingre |

55/80 kW/hk |

3232 MN |

3,20 m |

8 |

Nylonfingre |

60/85 kW/hk |