Kverneland DF-1

Maximum Flexibility and Balance

Højdepunkter

Balanceret vægtfordeling Forbedret sikkerhed og manøvredygtighed Uhindret udsyn bagud Til gødning af rækker med en præcisions-frøsåmaskineBeskrivelse

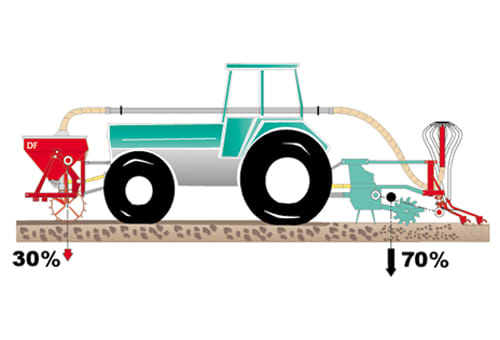

The modular structure of the Kverneland DF-1 ensures even weight distribution across the machine arrangement, giving the tractor maximum balance. This improves both safety and manoeuvrability, whilst at the same time giving the driver an unrestricted view over the entire machine set-up.

The Kverneland DF-1 are more flexible than conventional seed drills. They can be used for both conventional and precision sowing. For precision sowing the front hopper is fitted with special metering devices and the appropriate distribution head for row fertilising.

The Advantages:

- Balanced weight distribution

- Improved safety and manoeuvrability

- Unrestricted rear view

- To be used for row fertilizing in combination with a precision seed drill

Funktioner

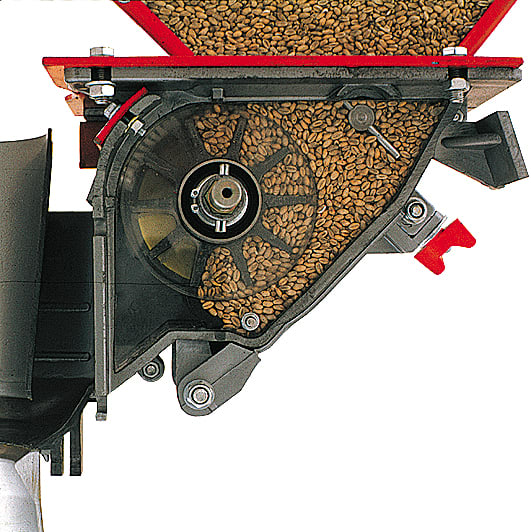

- The central metering device accurately metres any desired volume of seed from 2kg per hectare to 380kg per hectare

- For the sowing of fine seeds, e.g. rape or grass, the metering device can be infinitely adjusted to fine seed/micro-metering by means of a spindle, without any need for tools.

- The metering system is mechanically driven via the spiked landwheel running in the tilled soil.

- The metering device is centrally positioned and easily accessible under the hopper.

- Apart from the Signus, the pneumatic seed drills can be equipped with the Tellus GO and the IsoMatch Tellus PRO.

- IsoMatch Tellus PRO– the next generation universal ISOBUS Terminal

- Two ISOBUS interfaces in one terminal

- Multifunctional ergonomic design

- ISOBUS Shortcut Button (ICB)

- The IsoMatch Tellus PRO is the first ISOBUS terminal in the world with the capability to operate two different (machine) screens through one terminal, without the need to constantly toggle between screens.

- Via the ISOBUS connection, IsoMatch Tellus PRO automatically identifies the job control unit, which is located on the machine

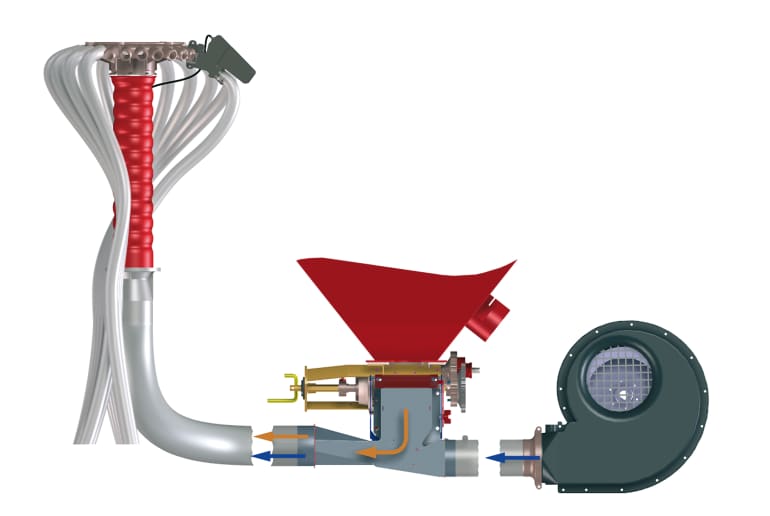

- The central, totally enclosed cell wheel of the metering device accurately measures the required volume of seed and discharges it into the venturi cone where it is mixed with the air stream and then conveyed through the diffuser tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

According to the individual requirements and soil conditions, the pneumatic seed drills can be equipped with Suffolk Coulter or the CX-disc coulter.

- The Suffolk Coulter of Kverneland is especially suitable for sowing after plough and offers coulter distances between 9.4 and 15cm.

- The coulter tip of special cast can be exchanged when worn.

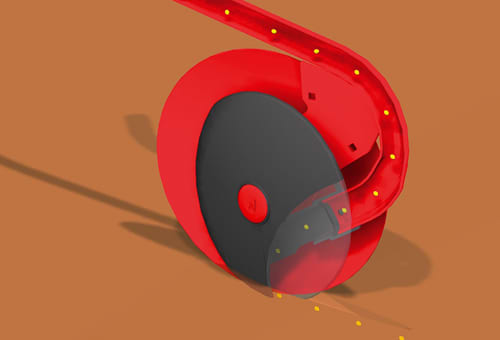

- The CX-disc coulter ensures exact seed placement under both wet and dry conditions

- Due to the combination of convex steel disc and flexible plastic disc, there is no need for independent scrapers saving the costs for expensive wearing parts.

- The convex steel disc forms a clean and clear furrow with light recompaction. The narrow profile allows higher working speed and the convex form of the disc ensures good depth control.

- The flexible plastic disc keeps the furrow open for exact seed placement. It cleans the steel disc and helps prevent sticking and blocking.

- Narrow and wide press wheels are available for special seeding conditions. These press wheels can be fully lifted in case of changing weather conditions.

- The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement.

- The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

- Due to the combination of the steel disc with a diameter of 325 mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

- Up to 35 kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface.

- An inter-row coulter spacing of 445 mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions.

- The press wheels can be set in fixed or floating position in order to be able to adapt quickly to changing weather, soil or working conditions.

Præcisionslandbrug

Lavet til smart, effektivt og nemt landbrug

IsoMatch GEOCONTROL er et avanceret software-program inden for IsoMatch Tellus og IsoMatch Tellus GO+, der hjælper dig med at styre alle ISOBUS kompatible Kverneland Group maskiner såsom sprøjter, spredere og såmaskiner! Kombineret med en GPS-modtager opfylder den fremtidens behov med hensyn til nemt, smart og effektivt landbrug!

Når der besluttes, hvilket udstyr der skal købes, er det ikke altid let at finde den optimale løsning på det brede marked, som der tilbydes i dag. Teknologien udvikler sig hurtigt, da vores traktorer og redskaber er mere og mere udstyret med højteknologisk elektronik. Vi forstår denne kompleksitet og er forpligtet til at give dig nemme landbrugsløsninger. derfor er disse omkostningseffektive ISOBUS Universal Terminals, IsoMatch Tellus PRO og IsoMatch Tellus GO+ lavet til dem der ønsker en nem og effektiv maskinstyring.

Med sine avancerede hardware og softwarefunktioner leverer IsoMatch Tellus PRO den optimale præcisionslandbrugsløsning til et alt-i-et kontrolsystem i dit traktorførerhus.

IsoMatch Tellus PRO er centrum for tilslutning af alle ISOBUS maskiner og en platform til kørsel af præcisionslandbrugsapplikationer. Det giver alt, hvad en landmand har brug for, for at få mest muligt ud af sine maskiner og afgrøder, samt med omkostningsbesparelser i gødning, kemikalier og frø ved automatisk sektionskontrol og variabel satskontrol. Med den unikke dobbeltskærms funktion giver det mulighed for at se og styre to maskiner og processer samtidigt.

Arbejd nemt, vær i kontrol.

IsoMatch Tellus GO+ er specielt udviklet til at styre maskinen på en enkel måde. Landmanden har fuld kontrol over maskinen på præcis den måde, han ønsker. Maskinen kan nemt sættes op med de bløde taster via 7" touch skærm og optimal kontrol under kørslen skal du bruge de hårde taster og drejekontakten. det har aldrig været så nemt at styre redskabet.

Det kan være dit første skridt ind i præcisionslandbrug, aldrig har det været så let.

IsoMatch Tellus GO+ gør det nemt at styre enhver ISOBUS maskine fra dit førerhus. IsoMatch GEOCONTROL giver dig mulighed for at opnå hørere udbytte, lavere omkostninger og gøre dit arbejde meget lettere. Denne licensnøgle er opdelt i to dele, sektionskontrol og variabel ratekontrol, som er tilgængelig fra IsoMatch Shop. Nu kan du købe den specifikke funktionalitet, du har brug for.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 2 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

Teknisk specifikation

Teknisk specifikation

Download brochureWorking Width (m) |

Hopper Capacity (litres) |

Weight (kg) |

|

DF-1 |

3.0 / 3.5 / 4.0 / 4.5 |

1150 (1700) |

570 - 800 |

IsoMatch Tellus GO+

IsoMatch Tellus GO+

IsoMatch InLine

IsoMatch InLine

IsoMatch Global 2

IsoMatch Global 2

IsoMatch MultiEye

IsoMatch MultiEye